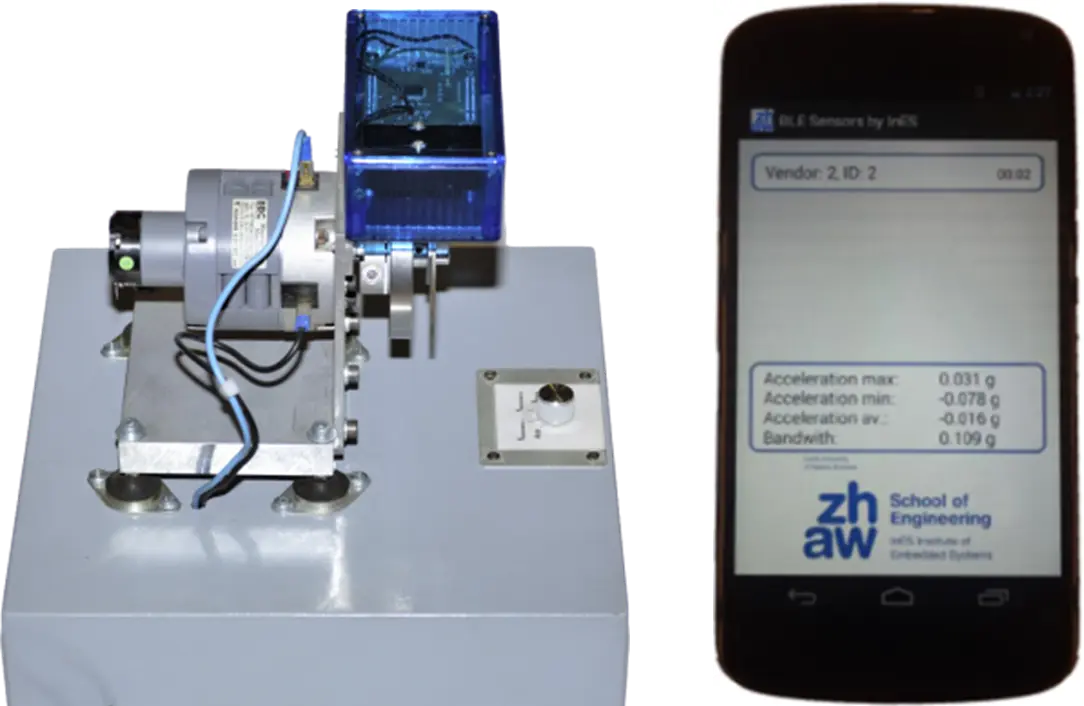

Condition Monitoring System for Industrial Drives

The monitoring of asset conditions and predictive maintenance in manufacturing requires sensors at critical points. Often, moving parts or bearings at production machines are monitored. Autarkic sensors allow a wireless installation also at locations where a cable installation is difficult or impossible.

The developed condition monitoring system collects the required electrical energy from the vibrations of the drive. At very low vibrations from 0.07 g, enough power is available to measure and send data in intervals of less than 500 ms. The maximum distance using ZigBee or Bluetooth Low Energy (BLE) is up to 50 m.