Higher light output with organic light-emitting diodes

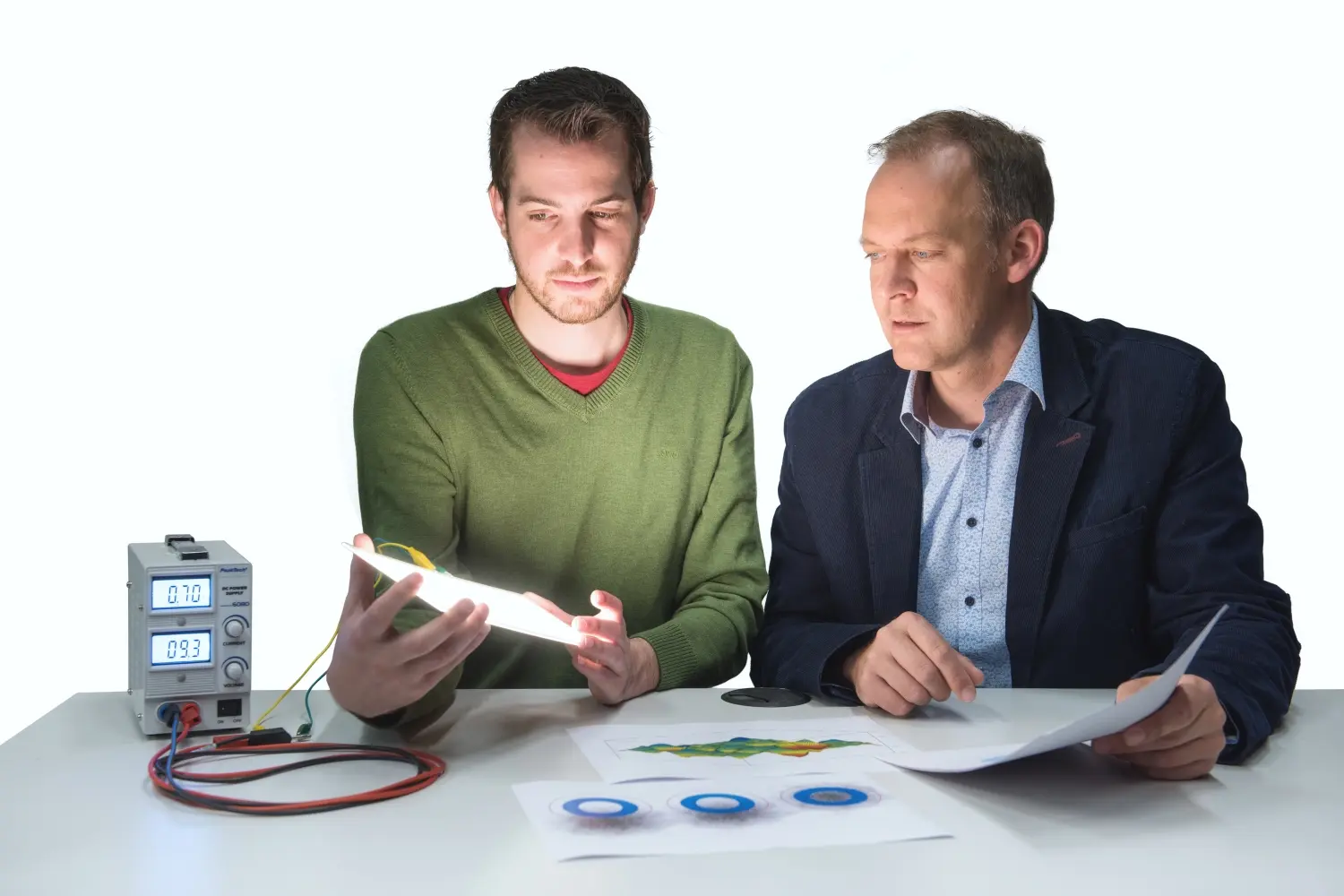

Research activities at the Institute of Computational Physics at the ZHAW School of Engineering include work on organic light-emitting diodes (OLEDs). In collaboration with partners, researchers are developing high-efficiency flexible OLEDs and producing them in their own lab.

Organic light-emitting diodes, or OLEDs, are already being used successfully in smartphones and tablets. But for lighting applications, OLED technology has not yet reached full market maturity. OLED lights are produced by applying layers of organic, semiconducting substances onto a substrate. This substrate can be made of glass, but it can also be a flexible PET film. “This unique feature of OLED technology distinguishes it from conventional LEDs, which cannot be produced on curved or flexible substrates”, explains Professor Beat Ruhstaller, who leads the Organic Electronics and Photovoltaics research team at the ZHAW Institute of Computational Physics (ICP). One area where this technology could be applied is the auto industry: OLEDs could be built into car roofs to provide extensive interior lighting or used to make curved, narrow tail lights and indicators. But before this can happen, there are two major challenges to overcome: increasing OLED light emission efficiency and extending their lifespan.

“To put it simply, the aim is to produce more light with the same amount of electricity by ensuring that less luminosity is absorbed by the device itself.”

Beat Ruhstaller, head of the Organic Electronics and Photovoltaics research team at the ICP

More light for the same amount of electricity

FlexOLED is a research project funded by the Federal Commission for Technology and Innovation (CTI). In this interdisciplinary project, the ZHAW School of Engineering is working with industry partners Nanograde and Fluxim as well as with another university, the École Polytechnique Fédérale de Lausanne (EPFL). The goal is to advance both the technology for light management structures in flexible OLEDs and the simulation methods. “To put it simply, the aim is to produce more light with the same amount of electricity by ensuring that less luminosity is absorbed by the device itself”, says Ruhstaller. Until now, researchers have usually tried to enhance brightness by applying a scattering film to the surface. This, however, has proved to be neither an optimal solution nor practical in production. “We are now developing a scattering structure that can be applied internally as close as possible to the light source instead of being applied on the outside”, says Ruhstaller. Using computer-aided physical models, the researchers simulate how light scatters through various particle concentrations in a scattering structure. The simulations, which have been carried out in collaboration with the ZHAW spin-off Fluxim, have shown that OLEDs can emit up to twice as much light if the structures are optimised.

Production in the ZHAW lab

The simulations show how the various light management layers can best be constructed. The ETH spin-off Nanograde is developing the scattering structure layer with a kind of nanoparticle ink. The EPFL is producing the anode layer; this electrode must be electrically conductive and transparent at the same time. Finally, the OLEDs are produced in the ICP lab, which has its own coating machine. In this project, OLEDs will first be produced on glass. Later, the researchers want to demonstrate that the structures also work on flexible PET film. “After the production stage, we need to prove by means of measurements that the OLEDs really are brighter”, says Ruhstaller. “The aim of the CTI project is to demonstrate that the technology which proved to be an improvement in the simulation actually works in practice.” If the results are positive, then Nanograde’s scattering structure layer could become suitable for serial production. Moreover, the test results are an important source of feedback for Fluxim in their efforts to further improve the predictive power of the simulation software.

At a glance

Project partners

Institutes and centres involved:Institute of Computational Physics (ICP)

Kommission für Technologie und Innovation (KTI)

Project status: ongoing