Practice-orientated and innovative - project-based learning at the ZHAW

From the idea to the built prototype. Students on the Mechanical Engineering program at the ZHAW School of Engineering work in a very practical way. At the Institute of Energy Systems and Fluid Engineering (IEFE), for example, they learn how to digitally design and lay out pump impellers. The prototypes are then produced using a 3D printer and subsequently tested. To test this knowledge, the IEFE has developed its own test rig, which is also used in pump impeller design research. With a great deal of initiative and creative solutions, impressive results are achieved.

Starting with an idea, mechanical engineers develop, design and optimise machines, plants and technical systems. The end result is a functional prototype. Students on the Mechanical Engineering course at the ZHAW School of Engineering are currently learning how to design gears and gearwheels and optimise manufacturing costs.

The design of centrifugal pumps is particularly challenging, as the flow calculations are complex. In order to convey the theoretical content in a practical and exciting way, the project module was redesigned in the 4th semester. Students now have the opportunity to deepen their knowledge of fluid dynamics acquired at the Institute of Energy Systems and Fluid Engineering (IEFE) in a practical and objective manner.

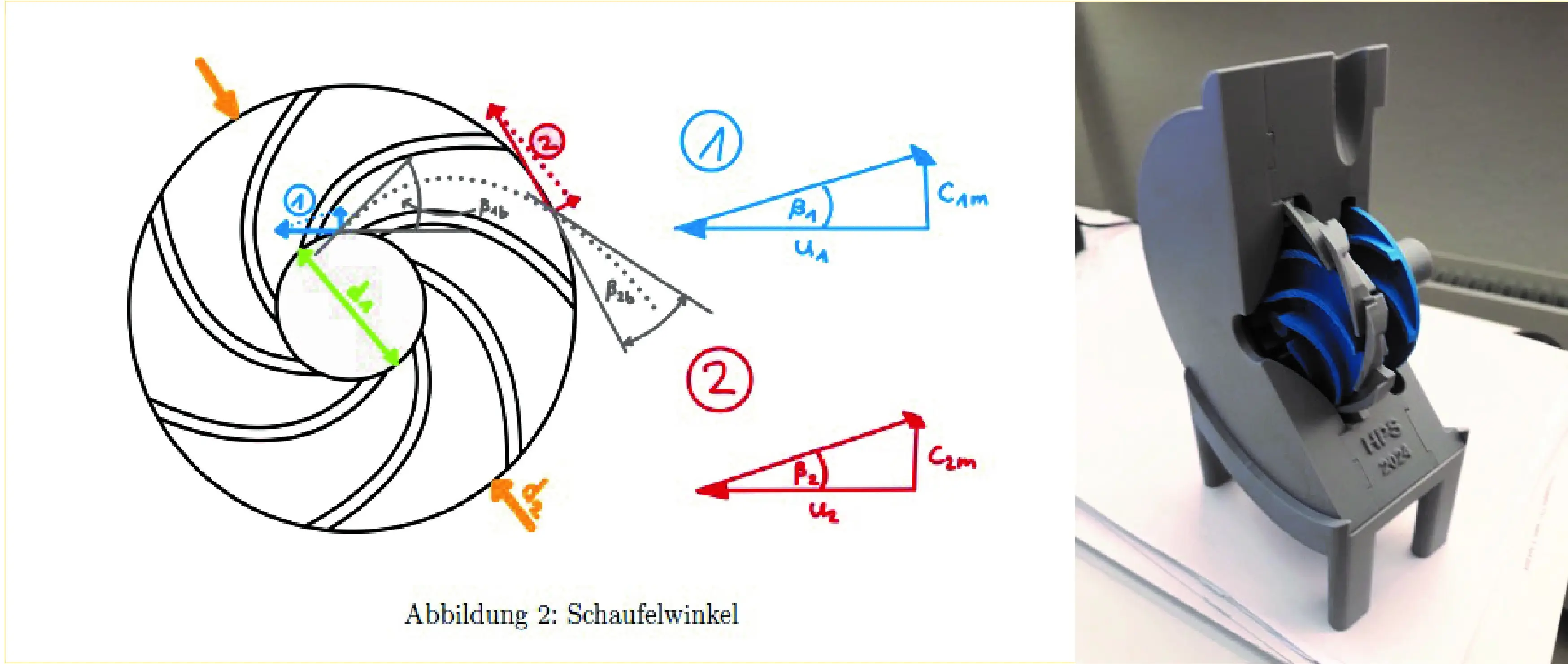

After just two theory blocks, the students work in groups for 12 weeks on a new task. This year's task was to develop a centrifugal pump for rainwater with a delivery head of 35 meters. They calculate and design pump impellers on the computer and construct them. They then produce them using a 3D printer. The resulting prototype is then tested.

A learning process that has more than proved its worth, as the results of this year's module showed. After the centrifugal pump had been successfully produced, one group encountered an unexpected problem during the test phase: the impeller deformed, jumped out of its axial anchoring and touched the housing. A consequence of the axial thrust forces - a well-known phenomenon in pump construction, as the lecturer explained. But how can this problem be solved?

The students looked for a promising solution and, after discussing possible causes with the lecturer, made some minor provisional changes directly to the practical workpiece by drilling some additional holes in the plastic impeller. With this empirical and pragmatic approach, they were able to observe the first improvements in the running behaviour during the next test. Motivated by this success, they went on to analyse the topic in depth from a theoretical perspective. This enabled them to optimise the design of the centrifugal pump and calculate precise relief bores. This resulted in a further developed model that ran smoothly and efficiently. One group of students was so motivated by the success that they developed a two-stage centrifugal pump immediately afterwards (see image).

This project-based learning promotes initiative and understanding - and leads to excellent results and enthusiasm for the subject. For the supervising IEFE lecturer Markus Weber Sutter, one thing is clear: if it is not (only) ECTS credits that count, but also a lot of passion for practical learning, then successful engineers will be trained who will pursue their profession with joy and passion.

Degree program

Bachelor of Science ZHAW in Mechanical Engineering, subject PM4

Lecturer

Prof. Dr sc. techn. Markus Weber Sutter

Mentioned term paper 2024 and pictures

David Margreth, Kay Mathis, Josua Müller, Elias Paravicini, Ataberk Sönmez