Valve mechanism for 3D printing with a pellet extruder

Description

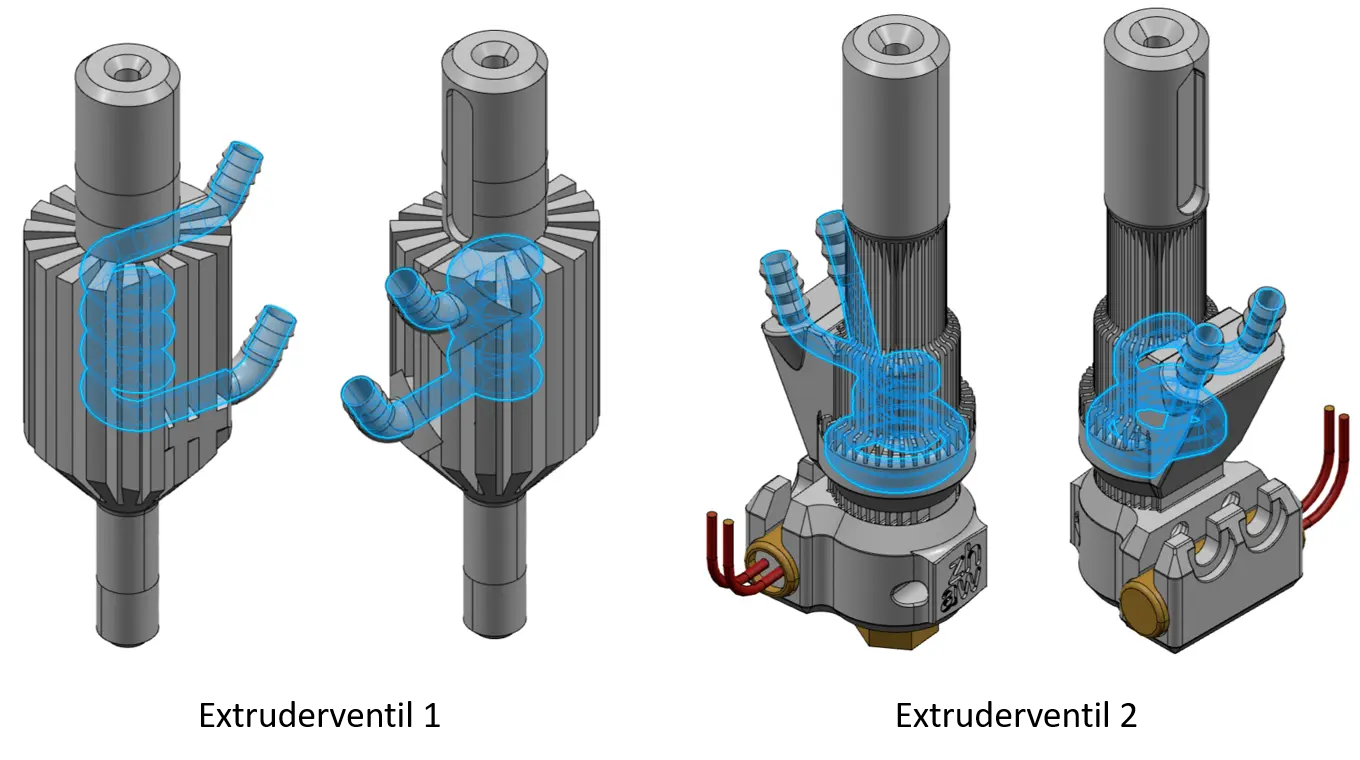

The development objective was to optimize the throughput and printing speed of a print head (extruder valve) for an FDM-3D printer.The approach focuses on an optimized separation between the hot melting area and the cool feeding area of the filament within the print head. This means that the area in which the supplied filament is melted should be thermally separated as sharply as possible from the cool supply area. This prevents the filament from heating up and becoming soft during feeding. The resulting stiffness and hardness of the filament ensures a higher feeding speed and better pressure conditions within the melting range in the nozzle and thus an increase in performance (printing speed) can be achieved during printing. An additional advantage is that there is less clogging of the filament, as the melt zone is sharply separated from the feed area.Such integrated cooling is only possible through additive production. Two prototypes were produced by selective laser melting in 1.4404 and successfully tested.

Key Data

Projectlead

Dr. Andreas Kirchheim

Project team

Tobias Fritsche

Project partners

3DDD GmbH

Project status

completed, 03/2017 - 03/2018

Institute/Centre

Institute of Product Development and Production Technologies (IPP)

Funding partner

Innosuisse