Digital Manufacturing as a Service Technology (DMAAST)

Description

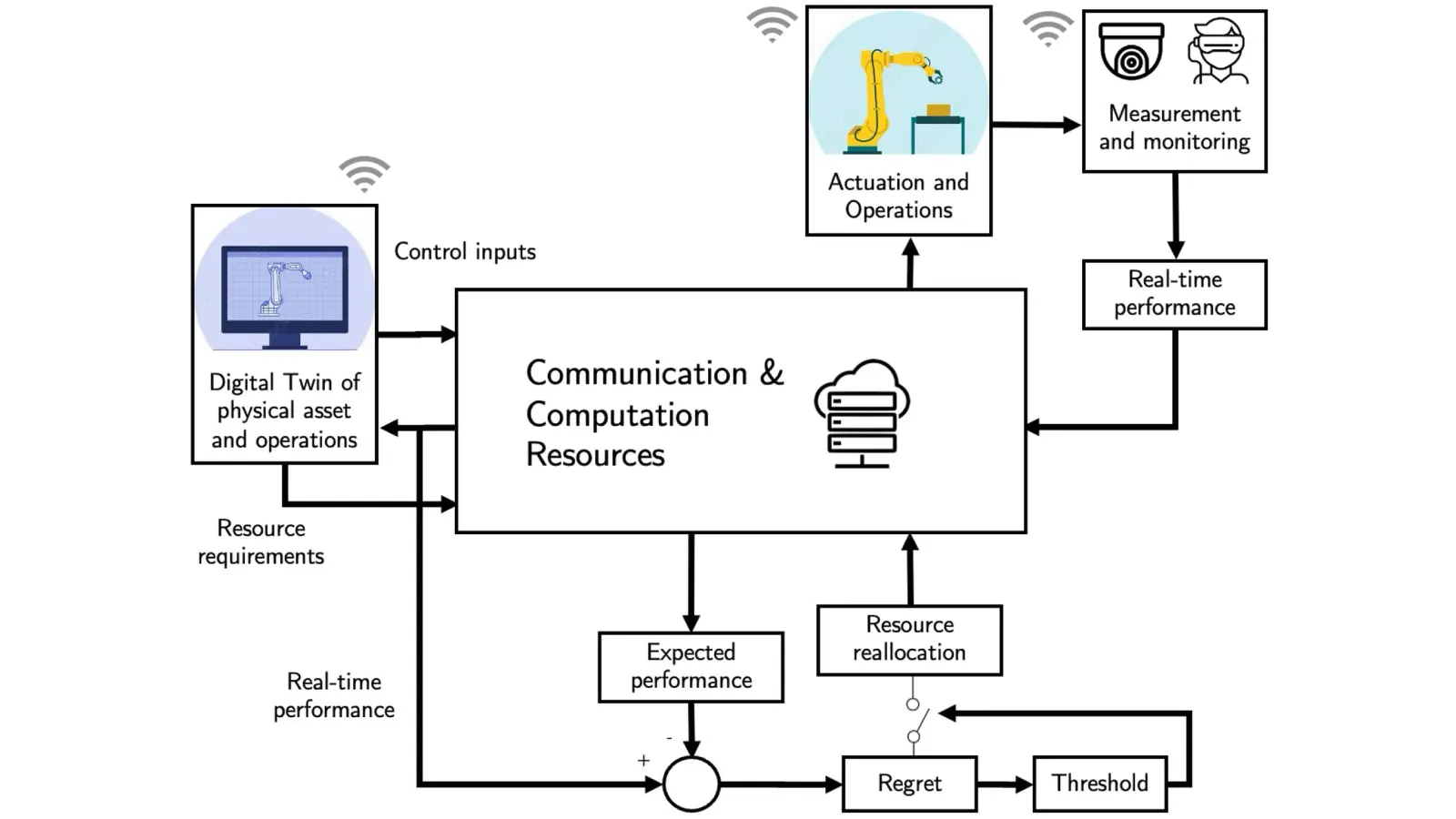

Digital Manufacturing as a Service Technology (DMaaST) is designed to improve the manufacturing ecosystem's resilience and adaptive capacity to external events through a Smart Manufacturing Platform structured into four layers: The data layer establishes a foundation for interoperable data exchange by creating mappings of ecosystem information using ontologies and implementing a decentralized knowledge graph (DKG) for trusted, real-time data integration across organizations. Next, a Digital Twin Layer is created, comprising two functional levels of digital twins, Low-Level Digital Twin which models the production lines of manufacturing services for two specific use cases, and a High-Level Digital Twin, which models the major value chain stages in the sectors relevant to the use cases. Both levels of digital twins integrate human expert knowledge, data-driven algorithms, and physical models to accurately reflect the manufacturing ecosystem.

The next layer is a Decision Support Layer, and it utilizes the data and models from the previous layers to inform a multi-objective distributed decision support system. This system merges multi-objective optimization approaches with advancements in Federated Deep Learning to make the digital twins actionable for guiding production decisions. The fourth layer is an Information Presentation and Sustainability Layer. It focuses on clear data presentation through dashboards and includes a module for assessing circularity, sustainability, and product traceability in line with the EU Digital Product Passport to improve production processes' environmental impact and remanufacturing potential.

The project ensures scalability, providing information for replicating and trying new manufacturing processes thanks to the included manufacturing services digital warehouse while assessing risks and opportunities for improvement. DMaaST innovations enable the manufacturing ecosystem to adopt the Manufacturing as a Service concept by smoothly evolving all the technologies from a Technology Readiness Level (TRL3) to a consolidated Technology Readiness Level 6 (TRL6) in two use cases in key sectors, aeronautics and electronics. Our role in it is to develop the decision support system integrating digital twins and learning and optimization capabilities which will equip the system to adapt to changes.

Key Data

Projectlead

Project team

Project status

ongoing, started 05/2024

Institute/Centre

Centre for Artificial Intelligence (CAI)

Funding partner

Horizon Europe

Project budget

456'816 EUR