ZHAW researchers are supporting the development of a ceramic implant system for the optimised treatment of cruciate ligament ruptures.

An innovative implant solution provides for a new method for the treatment of cruciate ligament ruptures. The process sees a bone-like, ceramic implant connected to the bone using a resorbable plastic implant liquefied with ultrasound, thus fixing the new cruciate ligament in the bone. Researchers from the ZHAW School of Engineering are currently developing test methods aimed at optimising and verifying the clinical applicability of the new solution.

Ruptured cruciate ligaments are one of the most common sports injuries that often require surgical treatment and unfortunately also frequently necessitate follow-up surgery. Surgical Fusion Technologies GmbH is developing an innovative treatment method that is designed to improve the healing of cruciate ligaments and simplify any subsequent surgical revisions that may be needed. A ceramic implant, which is fully integrated into the bone and replaced within a short time, physiologically fixes the replacement ligament in the bone. To ensure that the ligament can bear load in an optimal manner as soon as possible after the operation, the ceramic implant is also fixed in the bone with another implant made of resorbable plastic using ultrasound. Surgical Fusion Technologies GmbH is already using this ultrasound technology to fix tendons and ligaments during foot and hand surgery.

“The aim of the OsteoFusion project is to develop this method and the ceramic implant system to the point that it can be approved for clinical use,” explains Michaela Nusser, the Deputy Head of the Biomechanical Engineering research group at the ZHAW Institute of Mechanical Systems (IMES). The researchers are investigating the extent to which the geometry of the implants and the strength of the material would have to be modified in order to meet all requirements.

Test series on sheep

The project was initiated by Surgical Fusions Technologies GmbH and is being funded by Innosuisse. The Musculoskeletal Research Unit (MSRU) headed by Dr Karina Klein from the Vetsuisse Faculty at the University of Zurich has also been recruited to take part in the project. The MSRU researchers are to test the implant system on sheep. To this end, the implants will be implanted in the animals’ pelvic bone over a period of up to two years in order to ensure that the implant system heals without any problems and is also completely replaced within the optimum time window. The advantage of implantation in the pelvic bone is that, thanks to its size, several implants can be studied at the same time to compare their compatibility and long-term behaviour. “This approach allows us to protect the animals, and we also have to sacrifice far fewer test animals than would be the case if we were to insert the implant at the knee,” explains Karina Klein.

To guarantee the immediate mechanical stability of the OsteoFusion system not only for the patients, the anchoring strength on the cadaver bone is evaluated in several mechanical, so-called pull-out and cyclical tests carried out at the accredited test laboratory (according to ISO17025) of the IMES Biomechanical Engineering research group. “The implant that has been fixed in the cadaver bone is clamped in specially developed test devices and tested with respect to its tensile strength and stability,” explains Roger von Mentlen, who is heading up the project at the ZHAW.

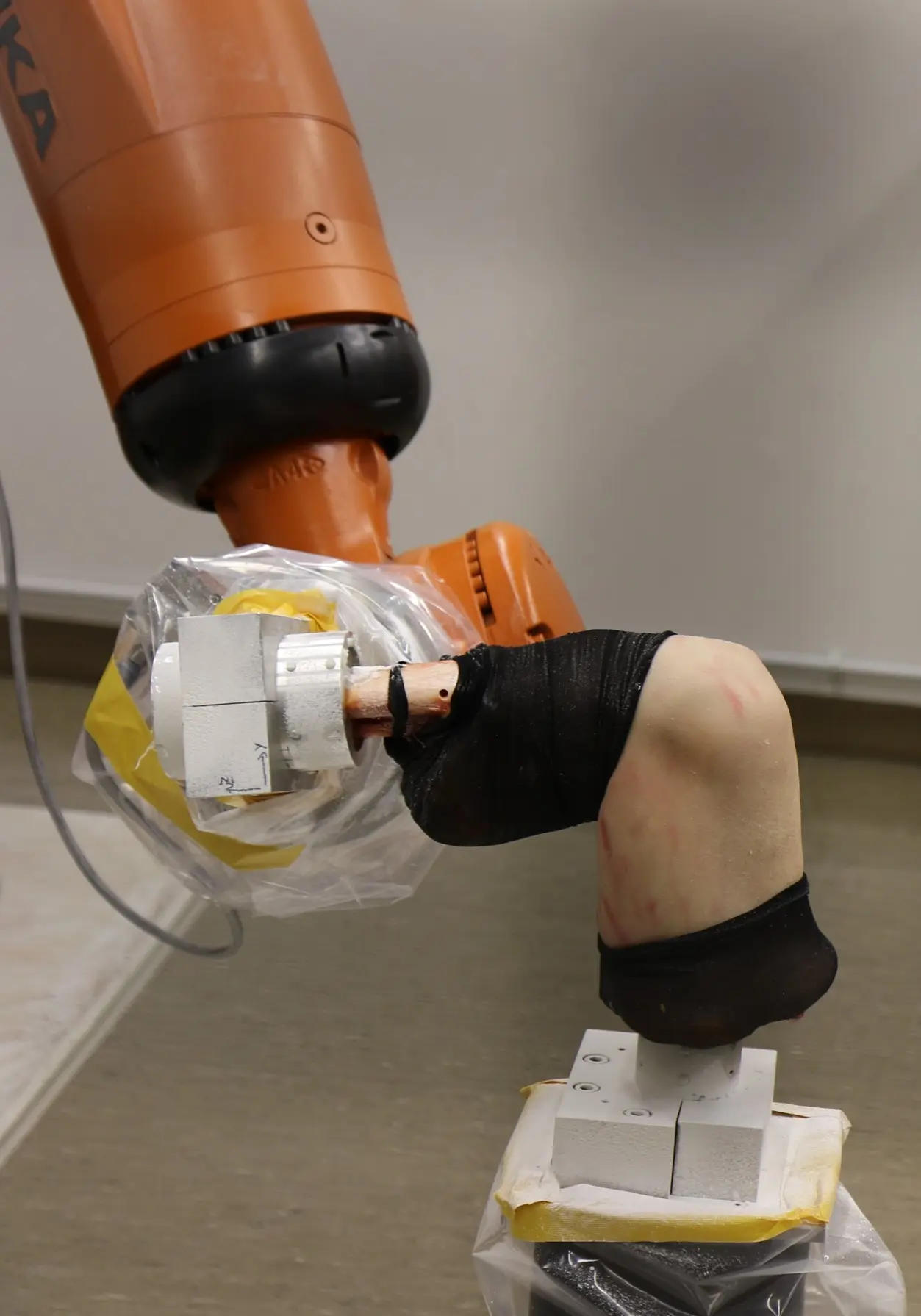

Simulating walking movements with industrial robots

A further objective of the ZHAW team is to subject the ceramic implant system to physiological tests using an industrial robot. To this end, doctors implant a piece of tendon as a cruciate ligament replacement in human knee cadavers and fix the tendon using ceramic implants. “The operated cadaver leg is then attached to the industrial robot, which uses it to simulate several walking cycles,” explains Michaela Nusser. This implant is then compared with a further implant solution from Surgical Fusion Technologies and a competitor implant. “Here, we want to see whether the anchoring of the ceramic solution is better than with the conventional products,” says the ZHAW researcher in explaining the purpose of the test series. Stumbling is also simulated with the robots – “although we still need to teach the robots a fair bit for this.” In addition, typical orthopaedic test series are conducted that cover all degrees of freedom of the knee. As a third sub-area, the IMES team is performing so-called finite element simulations. Nusser explains that in doing so they “want to investigate the transition between bone, implant and tendon and see just how mechanically robust the connection is.”

Challenge for ZHAW researchers

However, the project is not only beneficial in terms of offering a more efficient treatment of cruciate ligament ruptures, but also for the work performed by the researchers at the IMES. “For our institute, being involved in the project represents a major step forwards for our research. We are using our industrial robots to simulate a realistic situation for the first time by analysing the gait of the knee cadavers,” says Michaela Nusser in describing the project. Should the tests and optimisations on the ceramic implant prove successful, it is expected that the product will be launched on the market quickly. The project itself will run until the end of 2026.