ZHAW researchers use algorithms to optimise synthetically valuable enzymes

Enzymes are seen as a beacon of hope for the chemical industry as it strives to achieve greater sustainability. A research team at the ZHAW is optimising such enzymes for use in the industrial sector. The renowned journal Nature Communications recently published a research project carried out by the Institute of Chemistry and Biotechnology, which used an algorithm to successfully optimise an enzyme that can halogenate small molecules.

Enzymes are proteins that ensure that many vital processes in living organisms can take place. As natural biocatalysts, they can make chemical processes “greener”. The industrial sector is taking advantage of this fact by using enzymes to eliminate the need for toxic chemicals, rare metals and extreme reaction temperatures.

Enzymes need to be optimised for industrial use

After having evolved over billions of years, enzymes are optimised to perform their specific functions. In the industrial sector, however, enzymes have to perform different tasks to those they have mastered in nature. In order to also be able to use the natural “all-rounders” as part of industrial production processes, they need to be optimised for their new tasks. This takes place by means of “directed evolution”, a process that was recognised with the awarding of the 2018 Nobel Prize for Chemistry to the US researcher Frances Arnold.

ZHAW researchers are developing a customised enzyme for the halogenation of natural substances

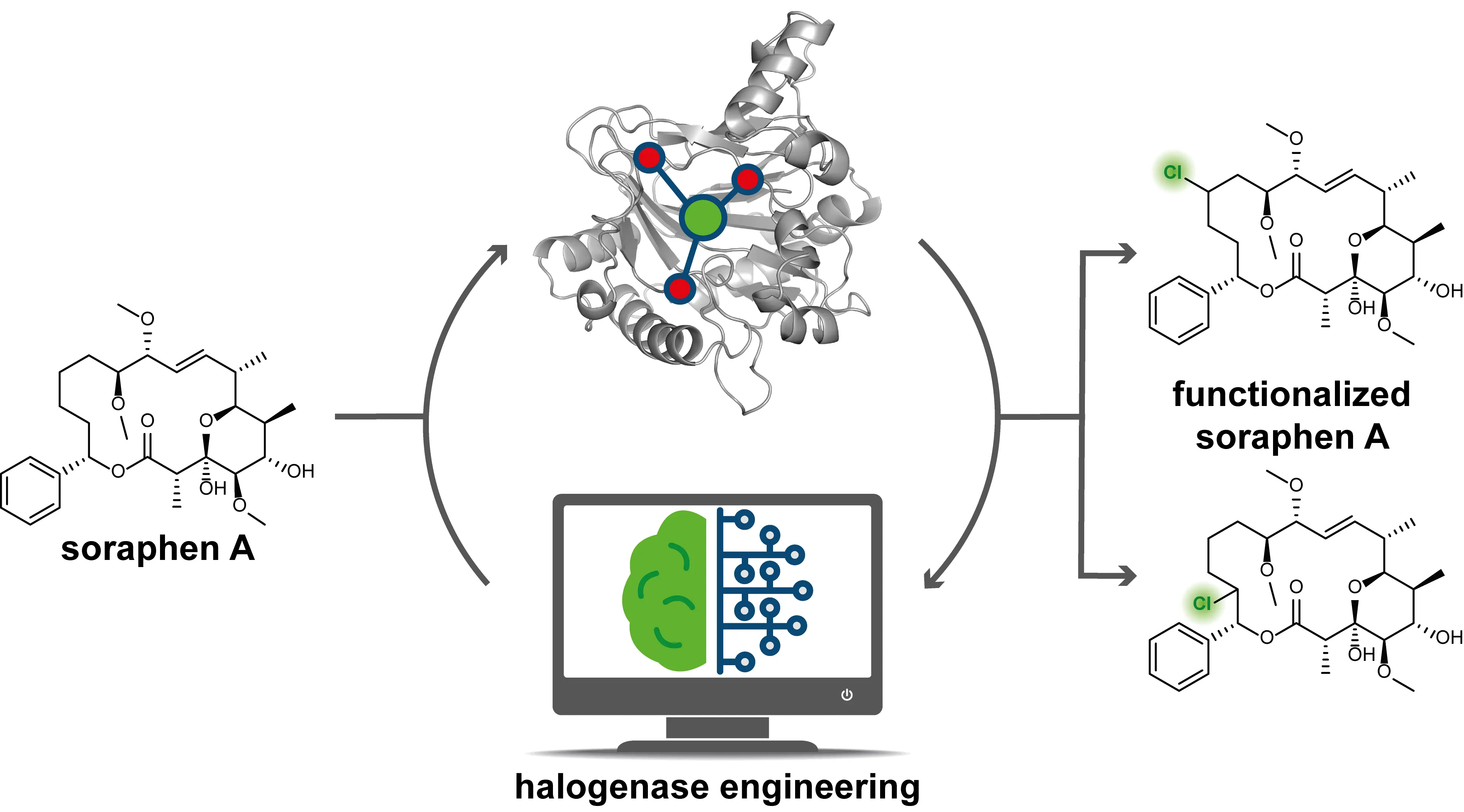

The research team headed by Rebecca Buller at the ZHAW Institute of Chemistry and Biotechnology in Wädenswil is utilising this process to optimise enzymes for use in an industrial setting. As part of the research project, which has been published in the renowned journal Nature Communications, the chemists have succeeded for the first time in modifying the wild-type enzyme “WelO5*” in such a way that it halogenates an industrially relevant natural substance that is in fact foreign to it. Halogenating enzymes are interesting for the chemical and pharmaceutical industry. As biocatalysts, they can very specifically insert chlorine or bromine, for example, into a chemical compound with the aim of modifying its bioactivity. The industrially relevant natural substance halogenated for the first time by the ZHAW’s customised enzyme “WelO5*” is a fungicide, i.e. an active ingredient that kills fungi. The researchers optimised the “WelO5*” enzyme further until they found a halogenase variant that could convert 300 times the amount of fungicide and 90 times faster. In doing so, they have massively increased the productivity of the halogenase and developed more selective derivatives of the potent fungicide.

Enzyme libraries and machine learning used in combination

The research team headed by Rebecca Buller achieved this feat using a pioneering combination of enzyme libraries and machine learning. “Using enzyme engineering, we are able to exchange amino acids within an enzyme and thus modify its activity. However, this process opens up so many different amino acid combinations that it is impossible to go through all of them experimentally. We therefore only produce and test a fraction of the possible enzyme variants in the laboratory – and use algorithms to help us predict even better combinations on the basis of this data,” explains Rebecca Buller with respect to the potential offered by this approach.

Halogenases open up new synthesis pathways in the area of medicinal chemistry

The halogenases developed by the researchers are already opening up new synthesis pathways in the area of medicinal chemistry. They can be used on a small scale in order to develop new active ingredients under laboratory conditions, as in the case of the fungicides presented in the publication. In a next step, the researchers will also optimise “WelO5*” for use on a larger scale and apply their method to other enzyme classes. The ZHAW’s halogenases could thus in future become a sustainable alternative in chemical and pharmaceutical production processes.

Downloads

- Media release “ZHAW researchers use algorithms to optimise synthetically valuable enzymes” (in German) (PDF 138.2 KB)(PDF 187,0 KB)

- Image 1:Soraphen A, a potent fungicide, is precisely derivatised using algorithm-optimised enzymes. The functionalised derivatives of the fungicide are characterised by their modified bioactivity. / Graphic © ZHAW/Johannes Büchler (TIFF 2.7 MB)

- Image 2:Using a tailor-made automation platform and machine learning, Rebecca Buller from the ZHAW Competence Center for Biocatalysis is optimising enzymes for use in the industrial sector./ Photo © ZHAW/Brüderli

Specialist contact

- Rebecca Buller, Head of the Centre for Biocatalysis and Process Technology, Institute of Chemistry and Biotechnology, ZHAW School of Life Sciences and Facility Management, Wädenswil. 058 934 54 93, rebecca.buller@zhaw.ch

- Centre for Biocatalysis and Process Technology: www.zhaw.ch/en/lsfm/institutes-centres/icbt/biocatalysis-and-process-technology/

ZHAW Media Relations, Wädenswil

- Cornelia Sidler, Media Relations, ZHAW School of Life Sciences and Facility Management, Wädenswil. 058 934 53 66, cornelia.sidler@zhaw.ch

Source/publication

- Büchler, J. et al. Algorithm-aided engineering of aliphatic halogenase WelO5* for the asymmetric late-stage functionalization of soraphens. Nat. Commun. 13, 371 (January 2022): https://www.nature.com/articles/s41467-022-27999-1