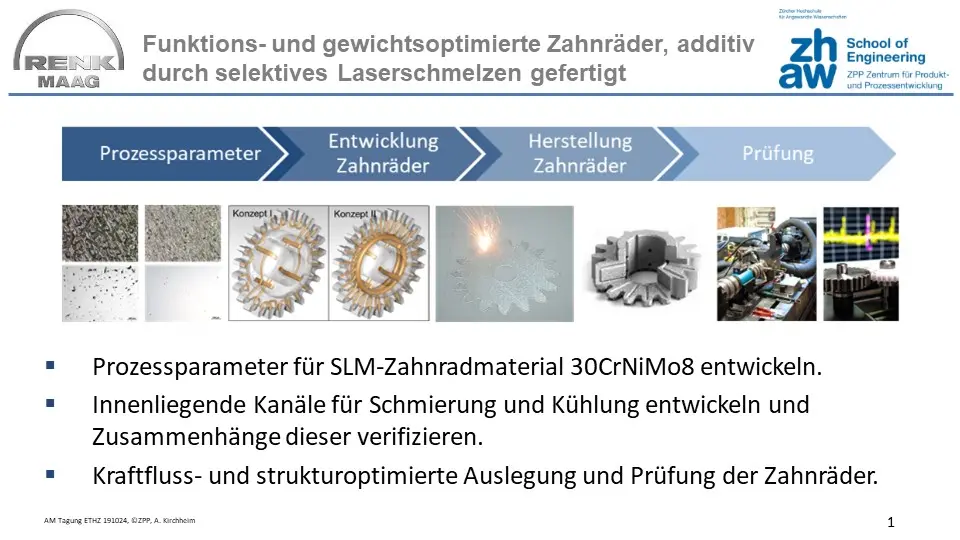

SLM gears: Function- and weight-optimized gears produced using the Selective Laser Melting (SLM) process

Description

Drive systems need to be designed to be lighter and more efficient. Smaller mass moments of inertia and optimized design for cooling, lubrication and tooth engagement can noticeably increase the efficiency of gears. Additively produced gears made of typical gear steels such as the 30CrNiMo8 offer great potential. This project combines knowledge in the field of gear design and additive manufacturing technology (Selective Laser Melting SLM

Key Data

Projectlead

Deputy Projectlead

Livia Zumofen

Project team

Dr. Andreas Kirchheim, Simon Winterberg

Project partners

RENK-MAAG GmbH

Project status

completed, 03/2017 - 06/2020

Institute/Centre

Institute of Product Development and Production Technologies (IPP)

Funding partner

KTI-Projekt / Projekt Nr. 25648.1 PFIW-IW

Further documents and links

Publications

-

Laser powder bed fusion of steel for quenching and tempering : from parameter study to application

2021 Zumofen, Livia

-

Laser powder bed fusion of 30CrNiMo8 steel for quenching and tempering : examination of the processability and mechanical properties

2020 Zumofen, Livia; Kirchheim, Andreas; Dennig, Hans-Jörg

-

Laser powder bed fusion of 30CrNiMo8 steel for quenching and tempering : examination of the processability and mechanical properties

2020 Zumofen, Livia; Kirchheim, Andreas; Dennig, Hans-Jörg

-

Function- and weight-optimized gear components by Laser Powder Bed Fusion (L-PBF)

2020 Zumofen, Livia; Dennig, Hans-Jörg; Kirchheim, Andreas; Stierli, Daniel; Waldburger, Michael Christoph; Winterberger, Simon