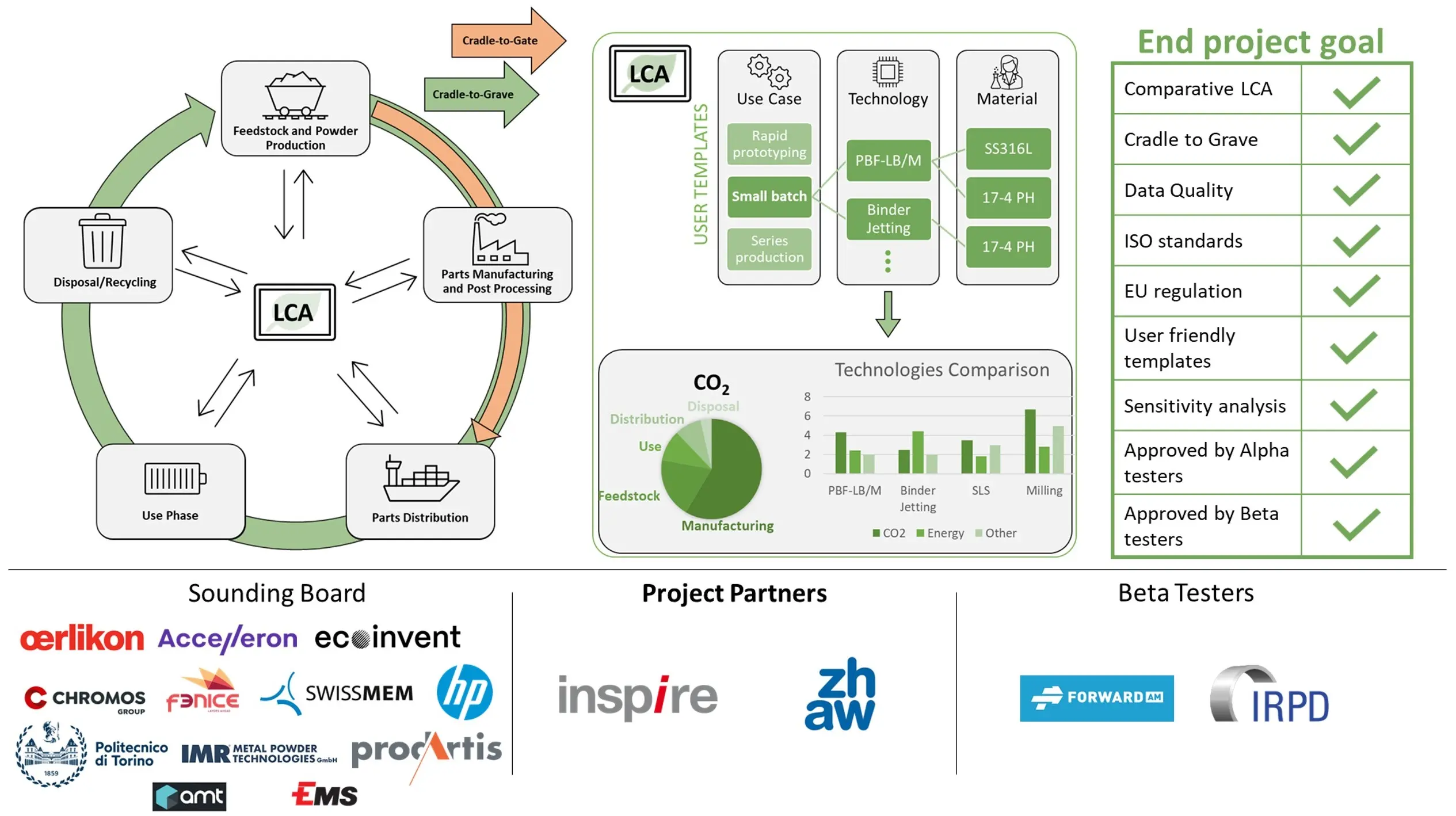

Evaluation System for Additive Manufacturing Sustainability (ESAM)

Our life cycle assessment for conventional and additive manufacturing of metals and polymers ensures that the best possible manufacturing method is chosen at an early stage of the development process. We also comply with EU regulations and ISO standards to promote sustainable production.

Description

The problem

Incoming European Union (EU) regulations, particularly the Ecodesign for Sustainable Products Regulation (ESPR), require companies to evaluate the environmental impact of a product's entire process chain. This is problematic for additive manufacturing (AM) due to calculation challenges like unclear resource distribution and lifecycle savings uncertainty, both currently not addressed by AM Life Cycle Assessment (LCA) services.

As AM grows (17% CAGR 2024 à 2030), and more companies adopt AM, a reliable comparative assessment methodology becomes crucial to identify the most sustainable manufacturing options and ensure regulation compliance.

The solution

This project will develop a comparative LCA tool to evaluate the environmental footprint of AM (metal and polymers) and conventional manufacturing (CM). It will incorporate sensitivity analysis and Monte Carlo simulations to manage data uncertainty, taking the shape of a user-friendly template for non-expert evaluation of specific use cases.

It will comply with ISO standards and address the current LCA gaps for AM covering the cradle-to-grave system boundaries, emissions during use and end-of-life phases.

Key data

Projectlead

Dario Puccio (inspire AG)

Co-Projectlead

Project team

Corinna Baumgartner, Hanspeter Sautter, Dr. Daniel Werner (inspire AG)

Project partners

inspire AG

Project status

ongoing, started 02/2025

Institute/Centre

Institute of Product Development and Production Technologies (IPP); Institute of Sustainable Development (INE)

Funding partner

Innosuisse - Innovationsprojekt

Project budget

359'885 CHF