Additive Manufacturing of Ceramics by Composite Microextrusion

Description

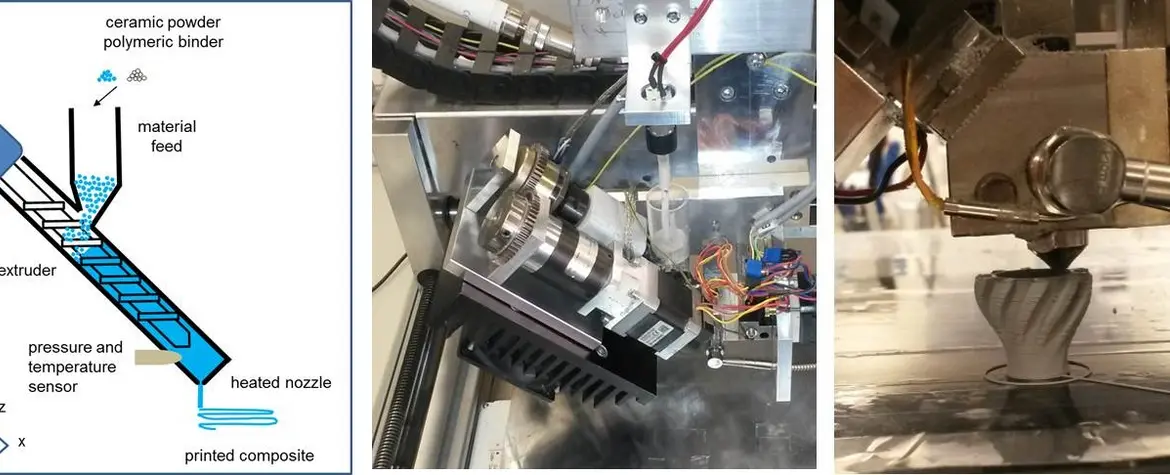

In the framework of a ZHAW internal project a new concept for 3D printing of ceramics based on a modified Fused Deposition Modelling (FDM) process was developed. Unlike conventional FDM filament printers, the starting material is a polymer-ceramic composite granulate material instead of a polymer filament as a feedstock. This granulate is melted in a self-constructed micro twin screw extruder under controlled pressure and temperature and extruded into fine filaments. The extruder is mounted on a 3-axis system so that the filament can be deposited in a controlled way to produce pre-defined 3D structures. The goal is to achieve reasonable print results for the composite material comparable to the FDM method and to convert it to ceramic components by debinding and sintering. Extensive parameter studies have been carried out for the construction of the printer, control and software, composition of the composite and extrudability, as well as debinding and sintering.

Key Data

Projectlead

Co-Projectlead

Prof. Adrian Fassbind, Tobias Moser

Project team

René Henke, Christiane Prukner

Project status

completed, 01/2013 - 12/2018