Section of Biocatalysis

«Biocatalysis as a complementary method to classical synthesis has great potential for the industrial production of bioactive and complex molecules»

Prof. Dr. Rebecca Buller, Head of Centre

In biocatalysis, enzymes (biocatalysts) are used either isolated or as whole-cell systems to produce new products, optimize existing synthesis routes or to supplement or replace critical steps in chemical production processes. With the help of enzymes, chemical reactions can be carried out more sustainably, selectively and efficiently without the use of environmentally harmful chemicals.

Modern technologies of molecular, cellular and systems biology make it possible to clone or de-novo synthesize genes from a wide variety of natural sources and to express the corresponding proteins in pro- and eukaryotic organisms. By means of so-called “directed evolution”, these enzymes can be optimized for specific chemical reactions if necessary. Nucleic acids are mutated rationally or randomly and the encoded enzymes are specifically selected for certain applications. Thus, biocatalysts with new properties can be generated, e.g. with improved enantio-selectivity, with new substrate specificity and higher activity or stability under harsh reaction conditions.

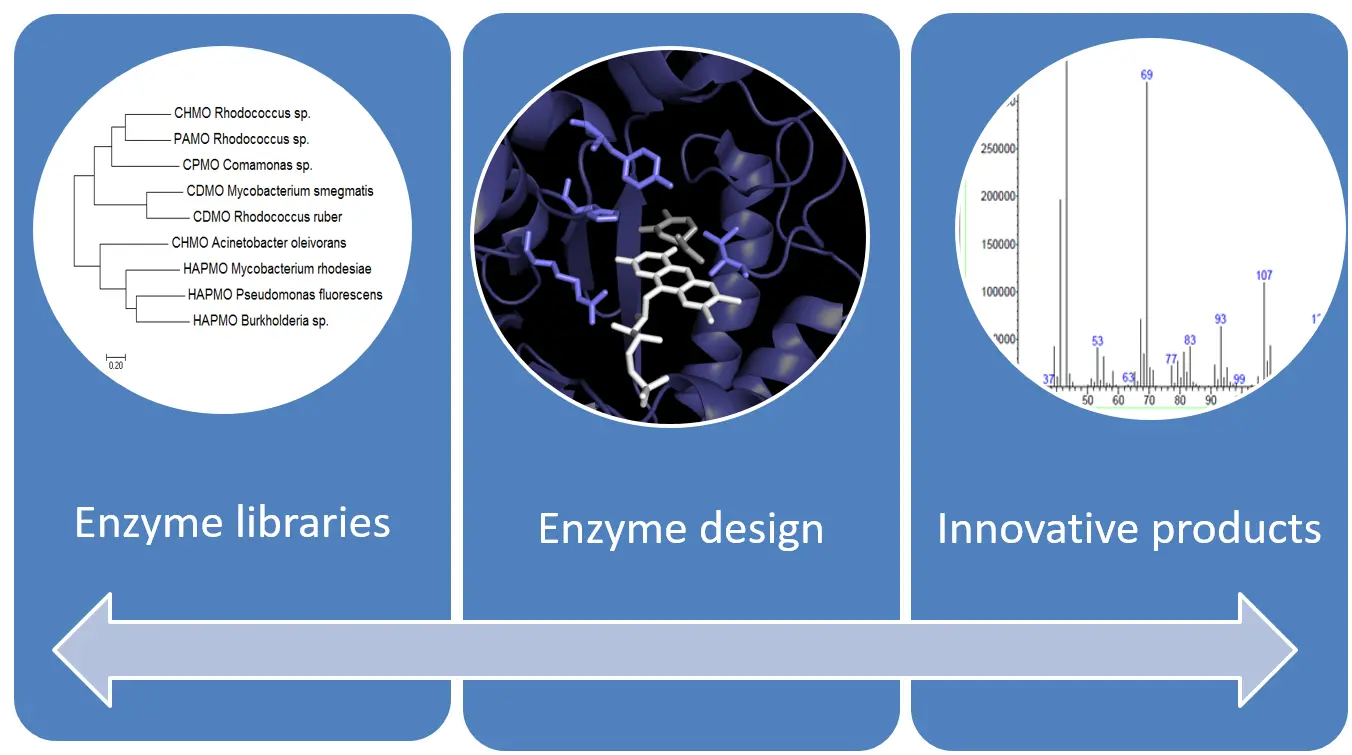

Enzyme libraries

The potential of natural enzyme variants for industrial biotechnology has not yet been fully explored. Sequence analyses can be used to identify enzymes with related properties from different organisms, the genes can be subcloned and expressed recombinant. The enzyme libraries developed in this way are examined with regard to their properties (pH and temperature optimum, solvent stability) and their substrate spectrum. An interesting class of enzymes e.g. is the group of enoate reductases. These oxidoreductases catalyze the asymmetric reduction of double bonds and have a broad substrate spectrum.

Enzyme design

The demand for tailor-made enzymes or whole cell catalysts for industrial applications in the pharmaceutical, food or feed industries are high. However, many industrially interesting chemical reactions cannot be carried out using naturally occurring biocatalysts because the natural substrate spectrum or the stability profile of these enzymes does not meet industrial requirements. By targeted or random mutagenesis, enzymes can be evolved with new catalytic properties as well as with improved thermal or pH stability, increased tolerance to solvents or improved activity.

Innovative products

The innovative use of enzymes can result in the production of novel bioactive substances with antimicrobial or anticarcinogenic properties that cannot be produced using currently available methods. Enzymes, which are able to modify peptides post-translationally, are investigated in our group e.g. for their possible application in the production of peptide therapeutics.