Chemical Engineering Group

«We develop innovative chemical processes.»

Dr. Peter Riedlberger

Head of Chemical Engineering Group

The main task of the Chemical Engineering Group is developing and researching more efficient and sustainable continuous chemical processes. The decisive approaches used are microreaction technology for the synthesis of heterogeneous catalysts and for catalysed processes, and continuous monitoring of chemical processes ('quality by design').

Research and competencies

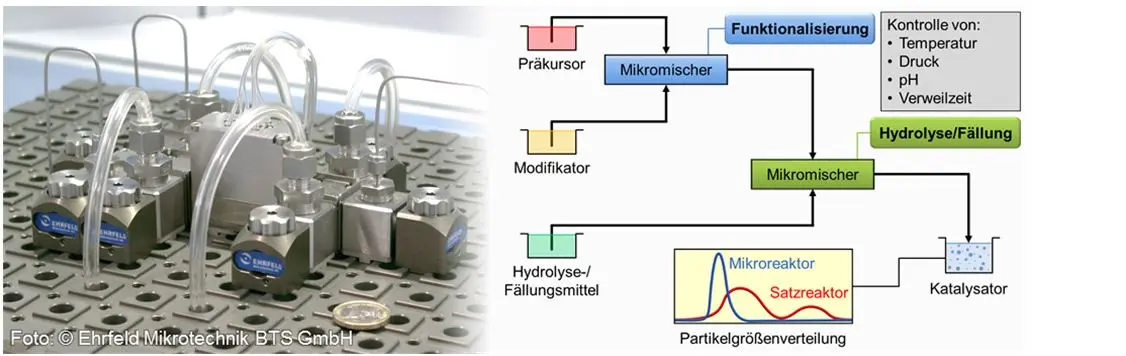

Preparation of heterogeneous catalysts in microreactors

Micromixers, with their small channels in the μm range, enable very short mixing times and therefore result in nm-sized particles with narrow particle size distribution during the synthesis of solids from solutions. They are therefore highly suitable for the production of solid catalysts, which are widely used in industry since more than 80% of all industrial chemical processes use catalysis. The aim of our work is to generate continuous processes on a microscale in order to allow simultaneous synthesis and functionalisation of the catalyst. This would be a major step forward in terms of process intensification with regard to energy and resource use as well as operating costs. One challenge we face is the stability of the process, which is primarily endangered by deposits of solids on the pipe walls (so-called fouling). By means of statistical design planning ('design of experiments'), all influences of the process parameters on the properties of the catalysts can be recorded efficiently, which on the one hand makes optimization possible, and on the other enables the manufacturing process to be understood.

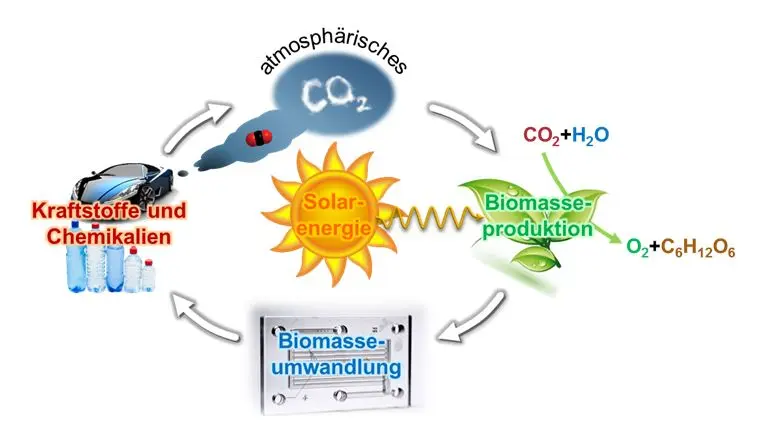

Efficient processes for the conversion of biomass into fuels and chemicals

The production of fuels and chemicals from biogenous raw materials (crops or biowaste) have now become a reality. In Europe, for example, biofuels are added to gasoline and diesel. Provided that the raw materials can be made available on a sustainable basis and that they are not in competition with the food industry, this opens up a path towards environmentally compatible products. However, this can only be achieved if the manufacturing processes used are efficient in terms of energy and materials. This is why our working group is researching the development of catalysed processes for transforming biomass to valuable products in microreactors. The very high surface-to-volume ratio in these small-scale installations allows for efficient heat exchange and thus precise control of the reaction conditions. In addition, the high mixing efficiency of these systems leads to more favourable turnover behaviour. However, the development of the heterogeneous catalysts required and their integration into the microreactor is a major challenge.

Chemical System Engineering

The monitoring and regulation of chemical processes play an increasingly important part in today's industry, which is dominated not only by global competition, but also by rapidly changing economic conditions, short product development times, strict environmental protection and safety regulations. Together with process modelling and optimisation, monitoring and control are crucial for the development of increasingly flexible and, at the same time, more complex production processes for high-quality products. Due to rapid cost reduction and a simultaneous increase in computing power of even the tiniest microprocessors, high-performance measuring and control systems have already become indispensable components of industrial plants.

In chemical processes, continuous, and thus cost-efficient and quality-securing, operation methods are widely used. In contrast, in biochemically-oriented industrial areas, this type of process operation still shows considerable capacity for expansion, since it places high demands on measurement and control technology. The research group therefore aims to develop control strategies and measurement methods that allow better monitoring and control of production operations, from cultivation in the (bio)reactor to product processing. At the same time, procedures for intelligent evaluation of process performance are investigated.

Publications

-

Ecker, Achim; Fourré, Caroline; Grandchamp, Tim,

2019.

Textilien färben mit Avocadoschalen oder Rotkohlblättern.

Transfer.

2019(2), pp. 4.

Available from: https://doi.org/10.21256/zhaw-18826

-

Martin, Oliver; Bolzli, Nicole; Puértolas, Begoña; Pérez-Ramírez, Javier; Riedlberger, Peter,

2019.

Catalysis Science & Technology.

9(17), pp. 4744-4758.

Available from: https://doi.org/10.1039/C8CY02574F

-

Ughetti, Manuel; Jussen, Daniel; Riedlberger, Peter,

2018.

Engineering in Life Sciences.

18(5), pp. 281-286.

Available from: https://doi.org/10.1002/elsc.201700141

-

Allemann, Christophe; Marti, Roger; Vorlet, Olivier; Martin, Oliver; Riedlberger, Peter; Leonhardt, Tobias; Gössi, Angelo; Riedl, Wolfgang; Segura, Jean-Manuel; Zinn, Manfred; Crelier, Simon,

2017.

Continuous processes and flow chemistry at the universities of applied sciences in Switzerland.

Chimia.

71(7-8), pp. 525-527.

Available from: https://doi.org/10.2533/chimia.2017.525

-

Martin, Oliver; Bolzli, Nicole; Riedlberger, Peter,

2017.

Continuous sol-gel synthesis of phosphated TiO2 catalysts in a microreactor [poster].

In:

Fall Meeting 2017 of the Swiss Chemical Society, Zurich, 21-22 August 2017.

Projects

Unfortunately, no list of projects can be displayed here at the moment. Until the list is available again, the project search on the ZHAW homepage can be used.