Section of Biosystems Technology

«Over millions of years, nature’s enzymes evolved to catalyze a wide range of reactions, creating a vast array of molecules. Biosystems technology taps into this potential, by recombining and altering them producing tailored chemicals through biotechnology.»

Nature has developed an impressive network of metabolic pathways in cells that make life itself possible. This interwoven network consists of countless individual chemical reactions that all take place simultaneously in one reaction vessel - the cell. Enzymes catalyse these reaction steps precisely and ensure selective product formation despite the complex environment. In addition, the principle of these multi-stage reaction cascades offers efficient energetic coupling of the individual reactions, in which even unstable intermediate products are processed directly.

Biosystems technology uses this natural principle to develop specifically adapted pathways (reaction cascades) that offer sustainable and customised solutions for biotechnological processes or can supplement chemical syntheses.

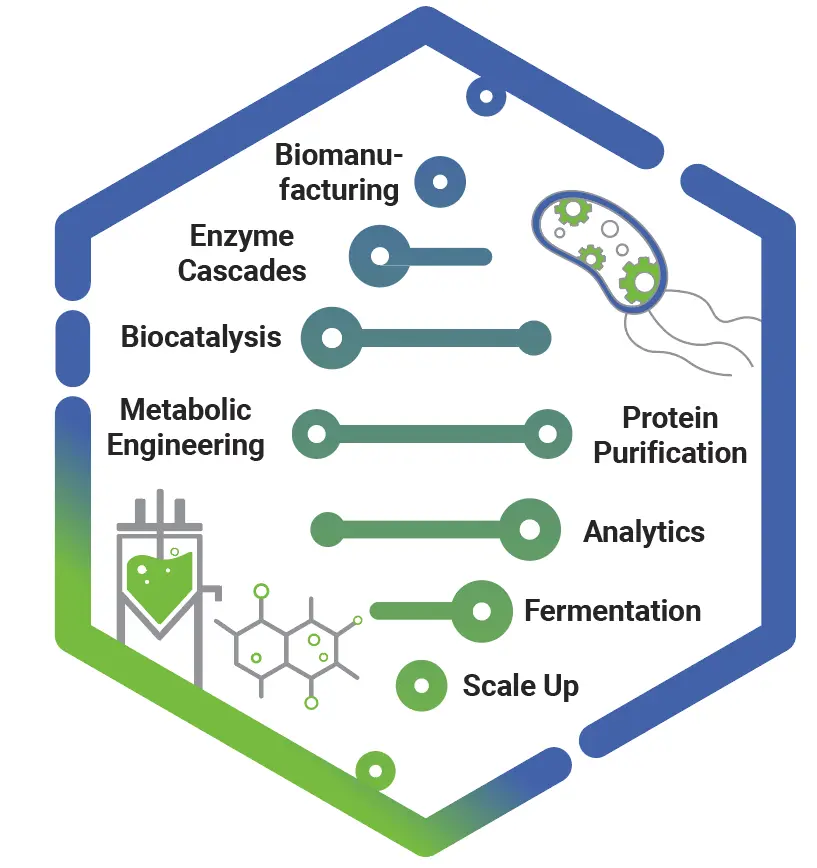

Competences

The Biosystems Technology Group brings together different expertise that allows succeeding all necessary process steps during enzyme cascade preparation.

This includes

- strain and expression vector design, preparation and optimization;

- lab-scale process optimization as well as scale-up;

- protein purification, biocatalysis development and optimization;

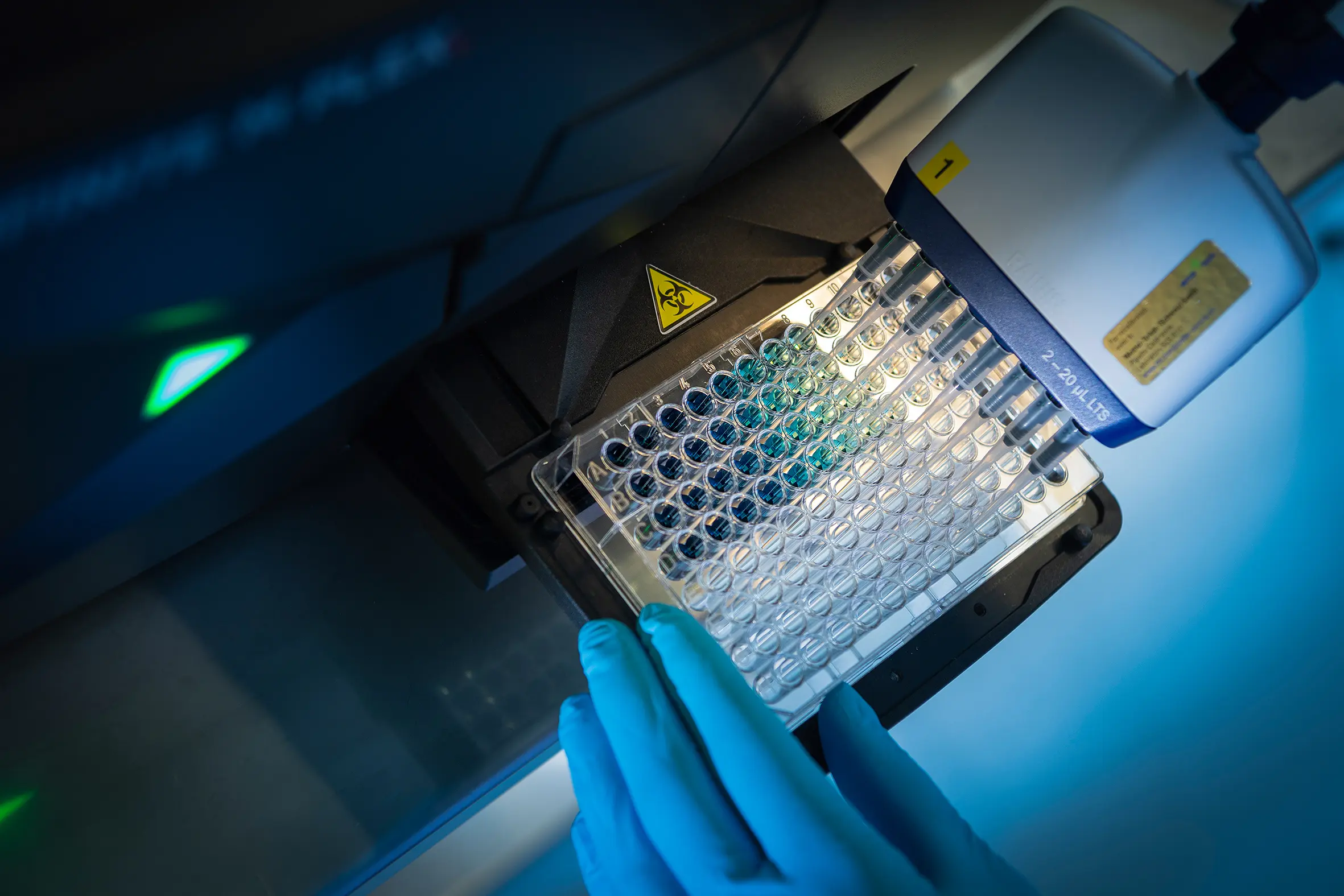

- and also screening methods in 96-well format or by MS-based analytics, involving also data analysis.

Research topics

Fermentation

We are equipped with 5, 10 and 30 liter reactors for fermentation of diverse organisms, supporting scale-up of fermentation processes. The biomass is either directly applied in whole cell biocatalysis, or in protein overexpression with subsequent purification.

Enzyme cascades

Enzyme cascades and whole cell biocatalysis are an emerging strategy for sustainable production of various chemical compounds. Major process benefits such as mild reaction condition, regio-, stereo- and enantiomeric specificity, as well as emission of intermediate purification render the approach highly promising for future application in industry. We pursue different design strategies, such as whole cell and cell surface display biocatalysis to establish efficient enzyme cascades. Success is monitored by different photometric assays or GC/ HPLC-MS-based analytics.

Protein production

Protein are highly valuable compounds for a wide variety of applications. We are experts in overexpression and purification of different protein types, ranging from enzymes to structural proteins. We apply state-of-the art techniques and adapted strategies specific to the protein of interest.

Genetics and whole cell cascade optimization

Microbial strain engineering can be crucial for an efficient whole cell enzyme cascades. Furthermore, the enzymes cascade itself needs to be fine-tuned to support efficient conversion to the desired product. Accordingly, we apply state-of-the-art genetic techniques to design suitable production strains. To design optimized enzyme cascades we rely on Modular Cloning which is based on Golden Gate Cloning, This approach supports highly modular design of cascade enzymes. Furthermore, we develop screening methods to identify the most successful production strains and cascade setups.