Fluid-Engineering and Refrigeration Technology

Our energy systems generally refers to technical equipment where energy conversion or energy supply processes are crucial. These typically transfer large amounts of energy, making high efficiency important from an economic and ecological perspective.

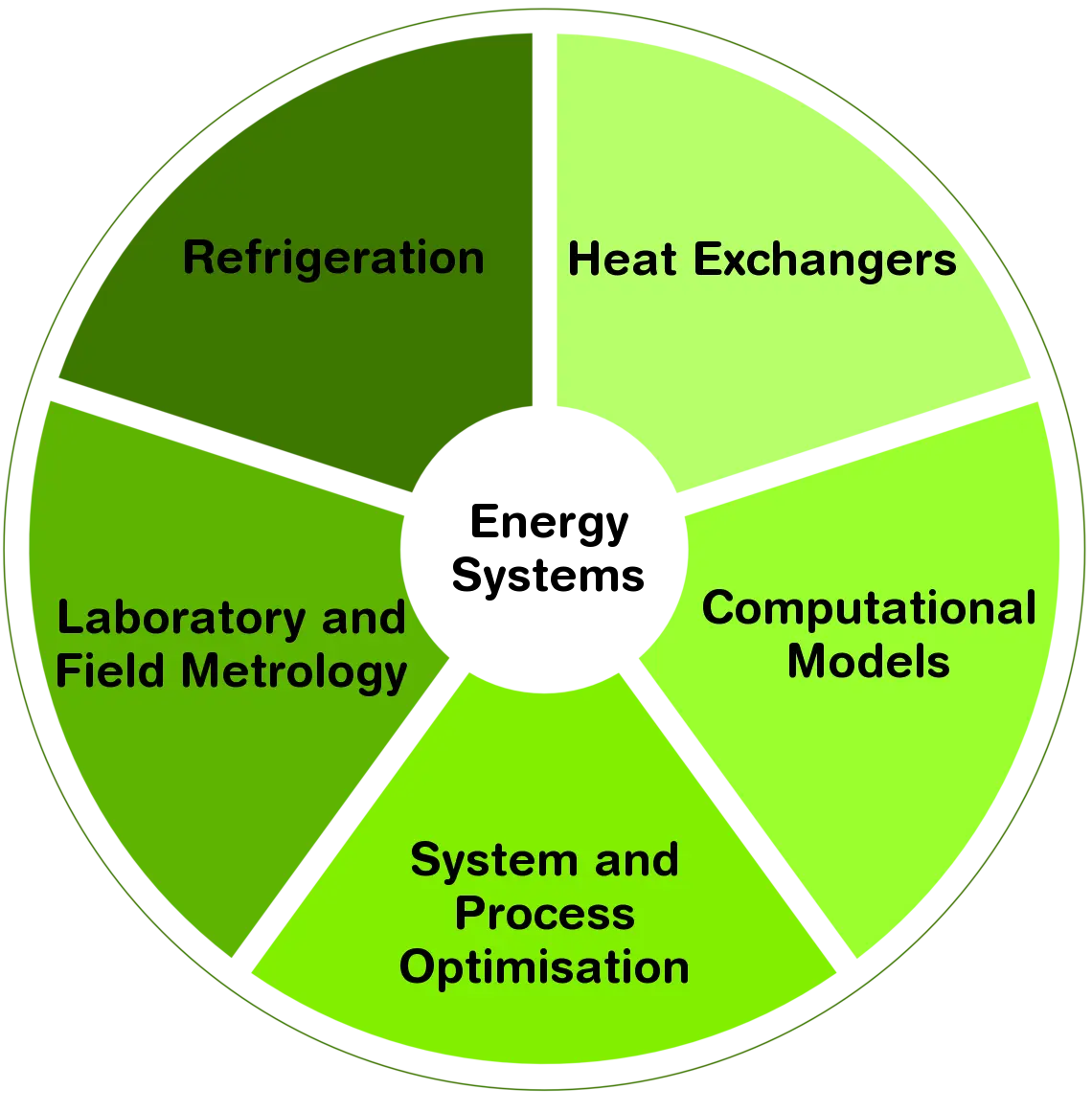

Core Area

Our energy systems’ field of competence deals with the most profitable utilisation of available resources. Complex energy flows are analysed at a higher system level and optimisation approaches developed. In this respect a detailed understanding of the underlying processes and technologies is crucial.

Refrigeration

Cooling units and heat pumps are among the dominant consumers of electric energy. About 14 % of Switzerland's demand for electricity can be attributed to these. More efficient refrigeration plants across the board means substantial energy savings.

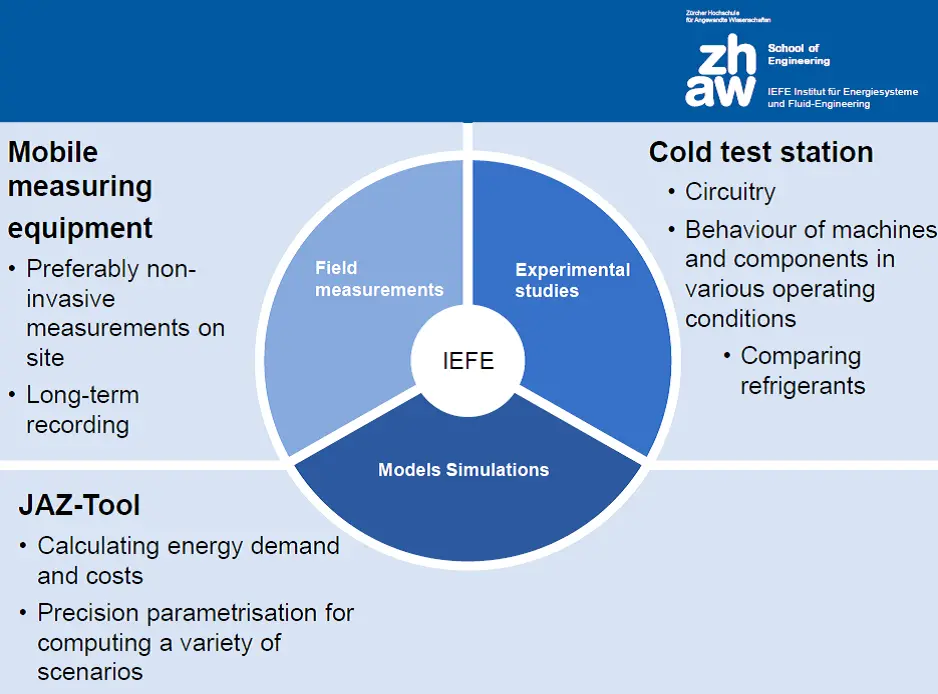

The Institute of Energy Systems and Fluid Engineering (IEFE) is heavily involved in refrigeration and is working on a measuring method for testing the performance of cooling units on site. Once the exact operating method of a refrigeration plant have been determined, specific improvements can be made. IEFE develops specific computation programmes for this purpose to determine a system's annual energy use based on various scenarios.

In addition to this, the Energy Systems department also deals with refrigerants and their use. The law mandates switching from chlorinated or fluoride refrigerants which are harmful to the environment to natural options, which will need to be implemented sooner or later. IEFE can aid designers and equipment manufacturers with its cold test facility, the only one in Switzerland, in this respect.

System and Process Optimisation

IEFE has vast expertise and years of practical experience in optimising systems and processes in a variety of thermal, fluid-dynamic, energy or production systems. The focus is always on energy efficiency and process safety and quality – with positive effects on profitability and the environment. The goal of IEFE is to create pivotal competitive advantages on the market for our clients.

Thermal computational models

Models are useful tools for designing and optimising systems as well as in comparing various technologies and can aid in selecting and rating machine components.

Depending on the application, the model needs to show reality at different detail levels. Simple models will suffice for qualitative evidence and rough estimates, whilst taking transient effects into account (e.g. thermal inertia) requires detailed, dynamic models.

The scope of thermal computational models is great and quite versatile. Where possible, modelling is accompanied by a field campaign of the respective object to validate the model.

IEFE uses a systematic approach in developing models. System boundaries are set, details abstracted and key process factors are defined for the systems or components being computed. The current state of research and development in the respective area is first identified through literature research.

The computational models are then designed on this basis, using the most popular software such as MATLAB or Simulink and Excel VBA, and relying on material databases to calculate state variables.

Laboratory and Field Metrology

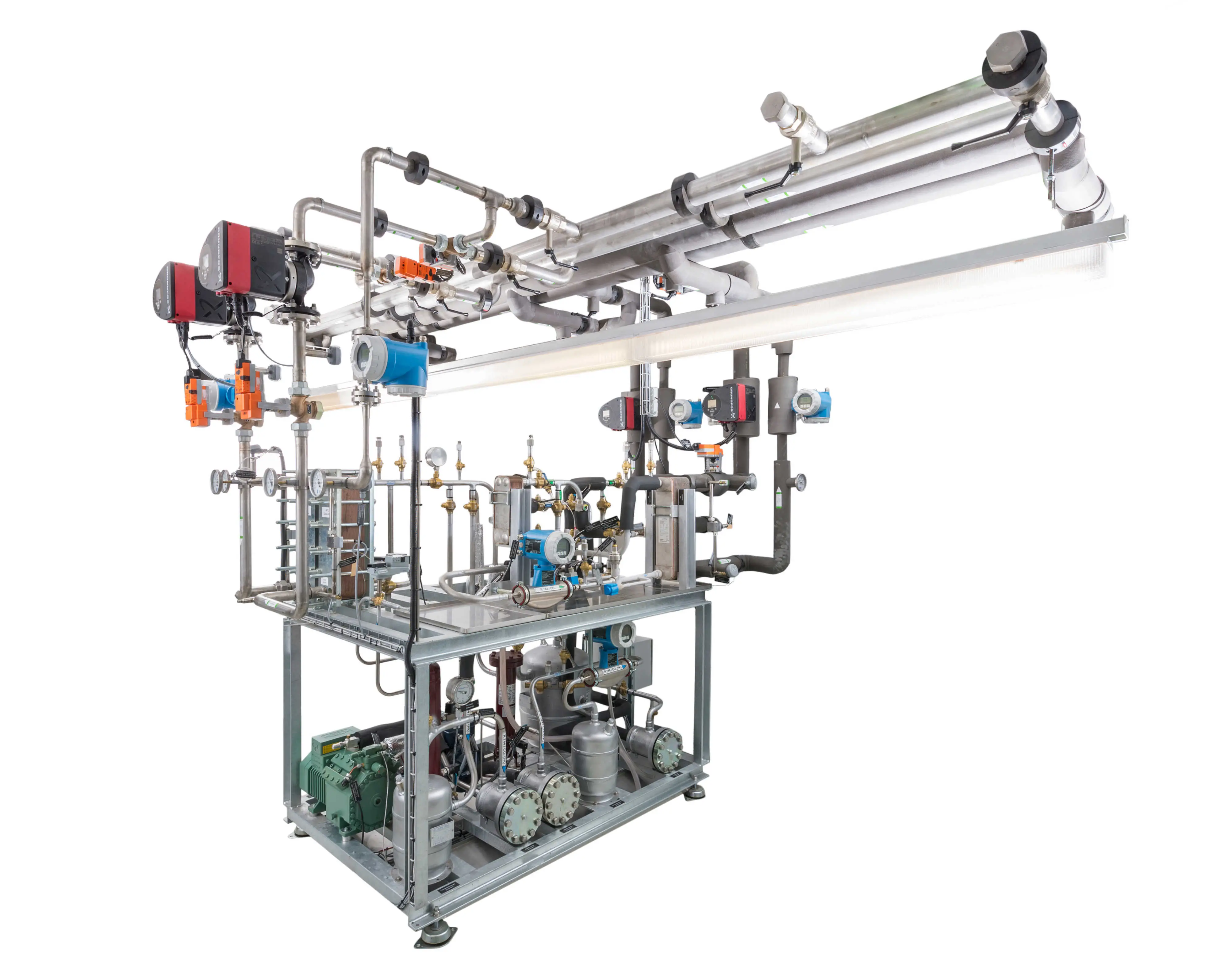

IEFE holds vast practical and theoretical expertise in laboratory and field metrology. We can examine mobile or small to medium sized machines, their individual components and entire systems at our in-house laboratory hall. Where necessary or requested by the client, IEFE will further design, build and commission test facilities with the related metrology.

Suitable programs are developed to record, display and analyse data. For larger and stationary machines, IEFE offers field measurements at the customer site. In the process we allow for the respective environmental conditions such as dirt, high temperatures, etc.

Data is logged wireless using different types of state-of-the-art data loggers. Here measurement data can be saved on site or continuously synchronised with a server, set up specifically for this purpose, over the internet. So upon request we can set up and run monitoring with remote access to the object being monitored.

Some of the metrology available at IEFE:

- Various temperature, pressure and hygrometry technologies

- Various flow meters (incl. ultrasonic measurement processes)

- Performance measurement (electric, thermal)

- IR camera

- PIV (Particle Image Velocimetry)

- LDA (Laser Doppler Anemometry)

- CO2 measurements

Findings from the field campaigns often form the basis for newly developed and improved machines, individual components for these or entire systems. IEFE develops possible solutions in close collaboration with our clients and reviews their feasibility and effectiveness in practical applications.

Heat exchangers

Heat transfer is pivotal in industrial and building technology systems. Fouling is a great problem in heat exchangers. Many mediums flowing through the heat exchangers will contaminate them, drastically reducing heat transfer efficiency over time. Special surface coatings can make it difficult for these particles to collect.

For severely contaminated mediums, a cleaning mechanism may be able to ensure a functional heat exchanger. The solution is often combining various approaches specifically for the specific requirements of the dominating process.

Other current issues with respect to heat exchangers are high temperature applications, manufacturing heat exchangers with non-metal materials and concepts for utilising waste heat in a variety of applications. IEFE uses field measurements and/or laboratory tests to examine existing or innovative heat exchanger technologies. This often requires custom measurements concepts and test stations along with ultra-precision metrology.

We will gladly provide our expertise to answer your questions. We will aid and advise you with new developments and improvements as well as metrology issues.