Installations and Equipment for Procedures and Processes

Pre-treatment

- Plasma pre-treatment chambers

- Sandblasting systems

Blends / Homogenization

- Extruder (single-/ twin-screw; g up to kg)

- Kneader

- Rolling mill

- Injection molding machine

- Mixers and dispersers

- Ultrasonic horn

- Material plotter

- 3D plotter (FDM, SLA, 3DP)

Chemical Reactors

- Stirred reactors up to 50 l (integrated rectification)

- Reactors for heterogeneous catalysis (sorption, fixed-bed, structured)

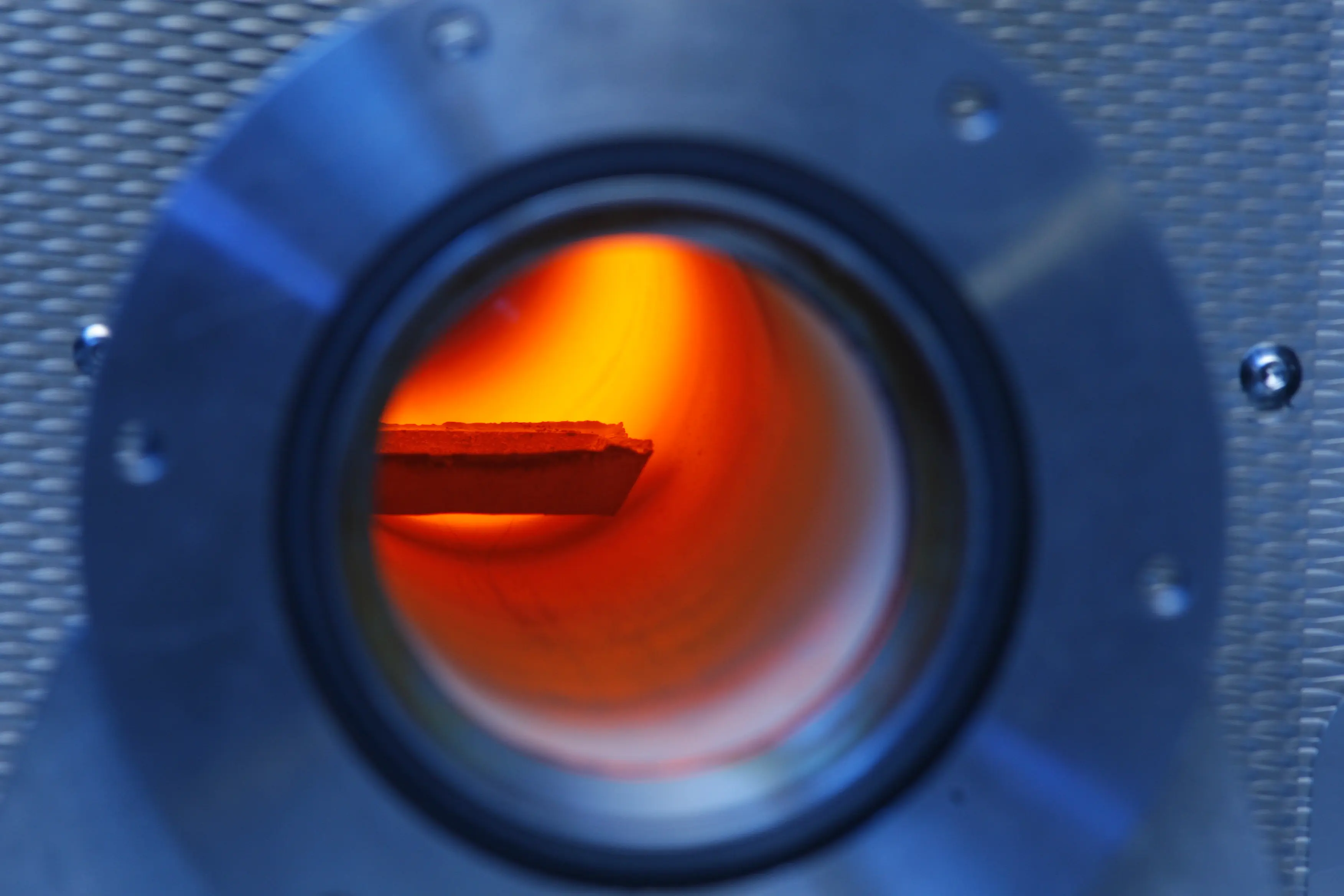

Heat Treatment

- Heat presses: heat- and vacuum presses up to 250 kN(temperature range: RT to 300 °C)

- Cabinet desiccator and circulating air ovens(temperature range: RT to 650 °C)

- High-temperature kilns with controllable gas atmosphere(temperature range: RT to 1800 °C)

Reprocessing

- Cold crushing plant, ball mills, impact mills, pin mills

- Sorption systems: adsorption-desorption systems (PSA, TSA) up to 80 bar, filling level up to 2m

- Membrane separators: pervaporation and ultrafiltration, membrane areas up to 3.5 m2

- Rectification and evaporation systems: laboratory and pilot installations up to 250 l

- Spray dryer, fluid bed dryer

- High pressure homogenizer

- Press filter up to 6 bar, centrifuge up to 11‘000 rpm

Coatings

- R2R coating systems

- Hot-melt coating systems

- Chill-roll system for extruder

- Spin-coater: up to 8000 rpm

- Spray stand (wet and powder)

- Dip coating: dipcoater (range: 0.2 to 170 mm/min)

- Foulard

- Wiper coating (automat. wiper table)

- UV belt dryer

- Electroplating

Conditioning

- Climatic test cabinet, 0.33 m3,temperature range: -42 °C to 180 °C, humidity range: 10 to 98% RH

- UV chamber (SUNTEST)