MSc degree programme at the Institute of Product Development and Production Technologies (IPP)

The IPP specialises in innovative product development in the field of mechanical engineering – from the birth of an initial idea to the final series product. It offers MSc degree programmes in the specialist fields of Mechanical Engineering, Mechatronics and Automation and Business Engineering.

Mechanical Engineering

The MSE in Mechanical Engineering covers all activities relating to the development, production, use and optimisation of machinery, materials, devices and products in the industrial, research and regulatory environment. The IPP carries out specialist projects in the areas of product, machine and device development, manufacturing processes, or additive manufacturing (3D printing), including simulations.

Further information on the MSE in Mechanical Engineering

Mechatronics and Automation

The MSE in Mechatronics and Automation deals with the design of autonomous systems using sensors, data processing and actuators. Since mechatronic technologies and automation are required in many different branches, the profile teaches systems thinking, which enables an understanding of complex processes. The IPP offers specialist projects in the areas of Industry 4.0, digital twin and VR/AR applications.

Further information on the MSE in Mechatronics and Automation

Business Engineering

The MSE in Business Engineering prepares students for a future in industry or service companies, or as consultants. Tasks await them in the areas of business development and business engineering, as well as in quality, risk, technology and innovation management. The IPP offers very application-oriented specialist project work in the fields of design thinking, business modelling and innovation playground.

Module

In the module browser, you can find the central modules (context modules [CMs], extended fundamental theoretical principles [FTPs] and technical scientific specialisation modules [TSMs]).

The IPP also offers the following decentralised specialisation modules:

- Cost Management in Development, EVA (3 ECTS credits)

- Novel Innovation Principles INNODES, TSM (4 ECTS credits)

Information events and application

Study Application

Registrations for the autumn semester (starting in September) are possible from the beginning of February until the end of April. For the spring semester of the next year (starting in February) from the beginning of August until the end of October.

Examples of MSc and project theses

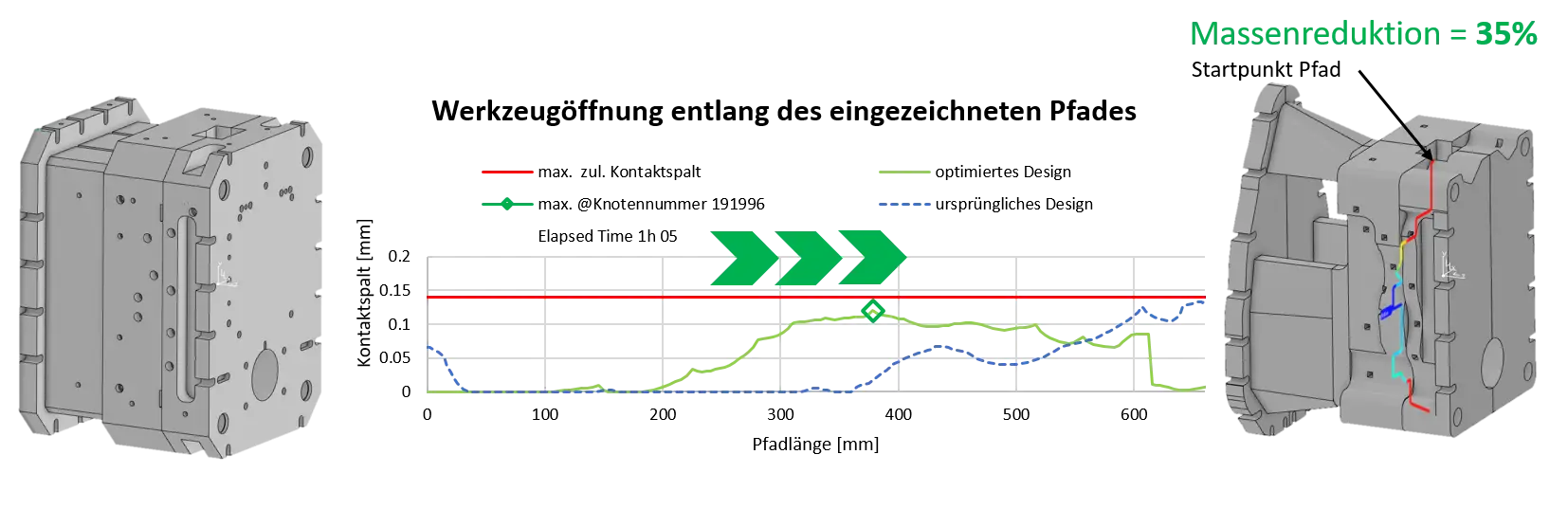

Lightweight construction of a die-casting mould with the help of topology optimisation

Example of a project thesis – Mechanical Engineering

Working in cooperation with Bühler AG from Uzwil, Switzerland, and on the basis of an existing die-casting mould design, analysis was carried out to determine how a weight-optimised design could be developed using topology optimisation methods, and to what extent this would be economically viable.

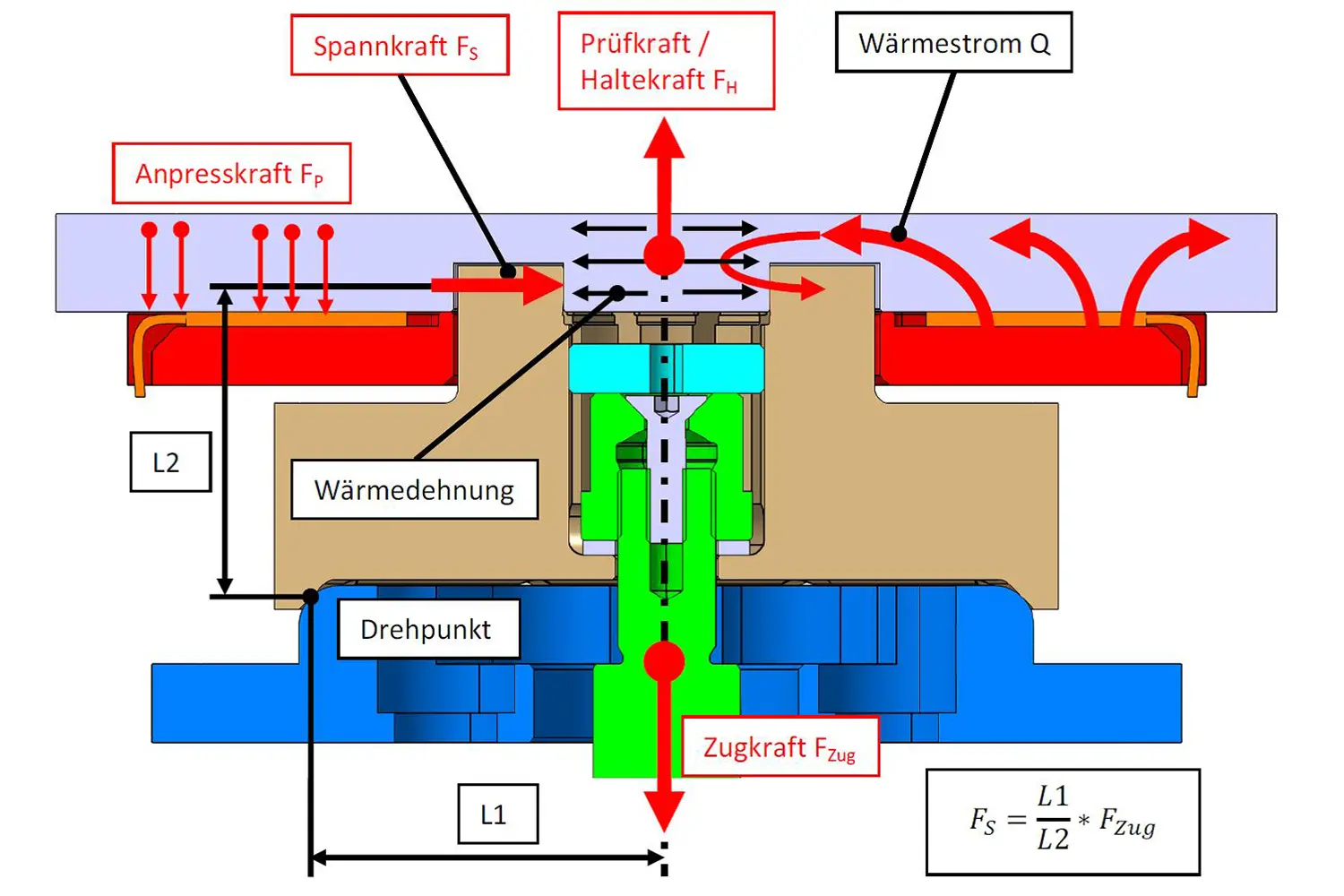

Greater precision in the additive manufacturing of metal parts

Example of a project thesis – Mechanical Engineering

The FDM (fused deposition modelling) 3D printer, with which it is very easy to produce components from plastic filaments, is probably the best-known 3D printer for additive manufacturing. While plastic is relatively simple to process, the additive manufacturing of metal parts on the basis of “selective laser melting” is far more demanding. Within the framework of this project thesis at the IPP, solutions were sought to further improve machines for selective laser melting.

Development of an optimised seat post for a gravel bike

Example of a project thesis – Business Engineering

The world of cycling is constantly evolving and every year it pushes the limits of both technology and performance. Gravel is one of cycling's new and popular disciplines and is enjoying increasing success with a growing customer segment. The discipline is characterised by all-terrain racing bikes that allow riders to ride comfortably on gravel roads without having to make any compromise in terms of the bike’s weight. To provide a comfortable ride on a gravel path, the induced vibrations and loads need to be reduced with the help of damping systems. However, efficient damping systems are heavy and thus significantly impair a rider’s performance. Micro-damping systems therefore have to be designed and integrated into the bike's frame and components. Since a considerable amount of the load is transmitted to the rider through the bike's saddle, a seat post with an integrated damping system offers a promising solution. The objective of this MSc thesis was the development of a comfort-optimised seat post for gravel bikes. The project was conducted in collaboration with SCOTT Sports AG, a sports equipment company based in the Swiss city of Fribourg. The first step in the product development process entailed conducting a benchmark analysis so as to assess the market and define the relevant specifications. After testing four of the world’s most popular comfort seat posts, it was concluded that none of the models exhibited the perfect combination of progressive stiffness, vertical deflection and low weight. After several designs and 3D models, the most promising solution proved to be a seat post with integrated polyurethane foam. A proof of concept was used to perform vibration tests that measure the spectral power density and transfer function. The results showed that the new design reduces the amplitude and energy of vibrations by more than 73%, which is 10% more than the closest competitor, the Cane Creek eeSILK. In addition, the saddle shifts along the seat tube axis, which does not influence the rider’s position and which leads to a pleasant riding experience.

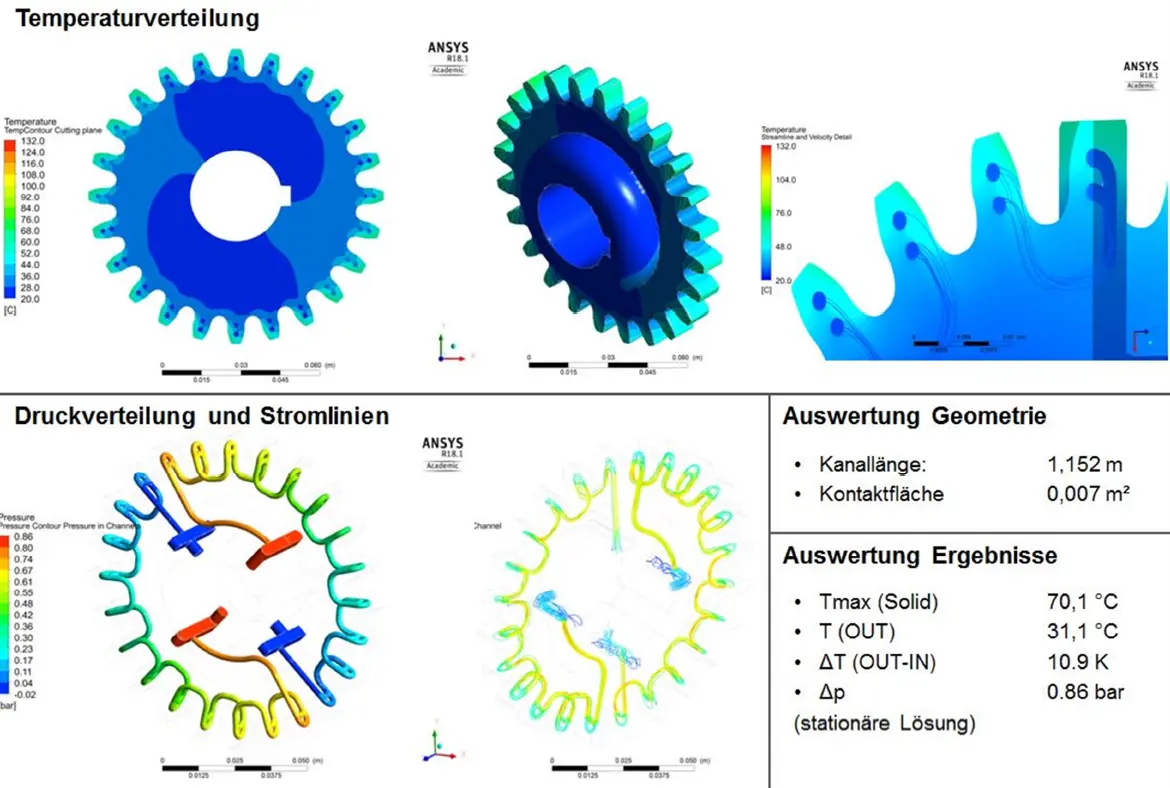

Additively manufactured gear wheels with conformal cooling

Example of a MSc thesis – Mechanical Engineering

Additive manufacturing, and in particular the selective laser melting process (SLM) and the degree of design freedom that this allows, make it possible for existing limits of manufacturability to be surmounted. One of the emerging optimisation approaches is the functional integration of internal structures. If the introduction of functional channels is now transferred to classical machine elements, promising opportunities arise. This was the origin of this development project. In the field of drive technology, there is a constant search for technologies that minimise the loss of power and motion transmission. Gear wheels can be optimised either through the use of lightweight design aligned with the power flow or through a reduction in lubrication. Since most of the lubricant is only required for heat dissipation, the amount used can be reduced through the application of an integrated cooling system, which in turn increases the efficiency of the gears. The additive manufacturing of functionally integrated gears to increase efficiency is an interdisciplinary field that has not been researched very much until now. The interaction of fluidic and structural-mechanical behaviour and the feasible level of quality form the development horizon here. This thesis aimed to develop a gear wheel with optimised internal cooling. After the additive manufacturing of the gear wheel, its functionality was also tested. For standardised FZG Type A test gears, various internal cooling concepts were developed on the basis of FEM parameter studies and SLM geometry samples. Based on CFD simulations, four concepts were compared with one another with respect to their temperature distribution and flow behaviour. The two concepts that achieved the most intensive cooling effect and a homogeneous temperature distribution were produced using the SLM process. Computer tomography testing was used to check the resulting quality of the integrated-component channel flows and whether all of the powder had been removed. Finally, the interior cooling was tested using a function test system and the cooling flows were recorded. Within this framework, two cooling concepts were developed with optimal properties in terms of their manufacturing process, structural mechanics and flow and temperature behaviour. It will only be possible to determine the optimisation potential of the concepts and the actual lubricant reduction by running application-oriented trials. Fundamental and transferable findings in this promising specialist field have, however, emerged. Through transfer and adaptation, these results can support the development of an application-ready product.