Project Example: Design of a low-noise axial fan for air-source heat exchangers

Numerical optimization of an axial fan considering acoustics and aerodynamics

Air-source heat pumps typically feature an external unit with an axial fan to blow air through the heat exchanger (Figure 1). Due to the annoyance (and regulations) of the noise emissions of the fan, manufacturers try to achieve as low-noise configuration as possible while keeping the target pressure and volume flow. This project aimed to develop a low-noise fan with reasonable efficiency at a set of operating points within structural and geometric constraints.

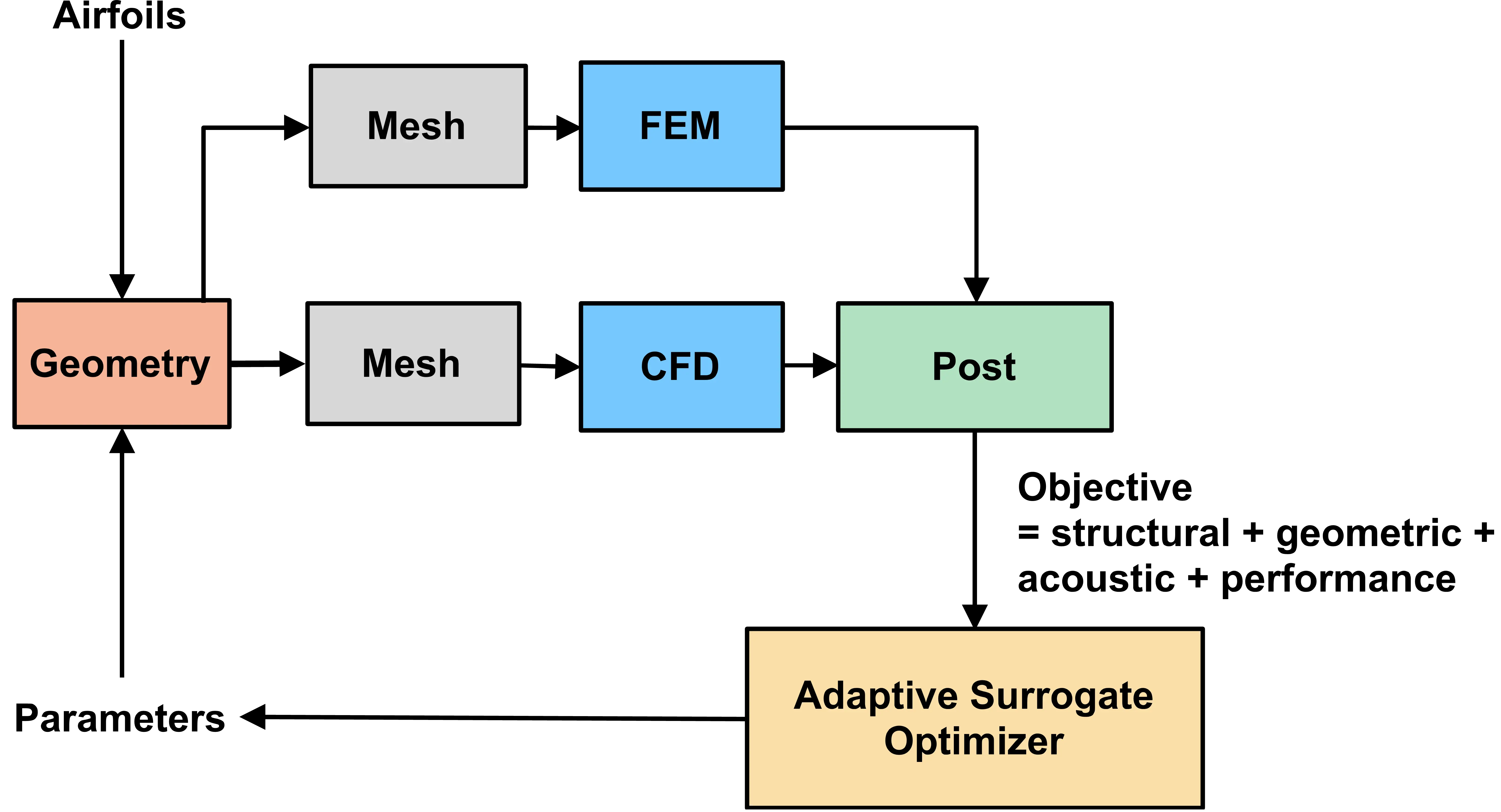

To obtain a low-noise fan design, an automated optimization procedure was developed (Figure 2). This optimization is multidisciplinary as the merit function incorporates the effects of aerodynamics (RANS CFD), acoustics (tonal and broadband models), structure (FEM), and geometric constraints. For the optimization, an adaptive surrogate-based optimizer was utilized. This type of optimizer not only samples the design variable space and creates an initial surrogate model based on the evaluated points, but adaptively improves the surrogate when new evaluations of the merit function are calculated.

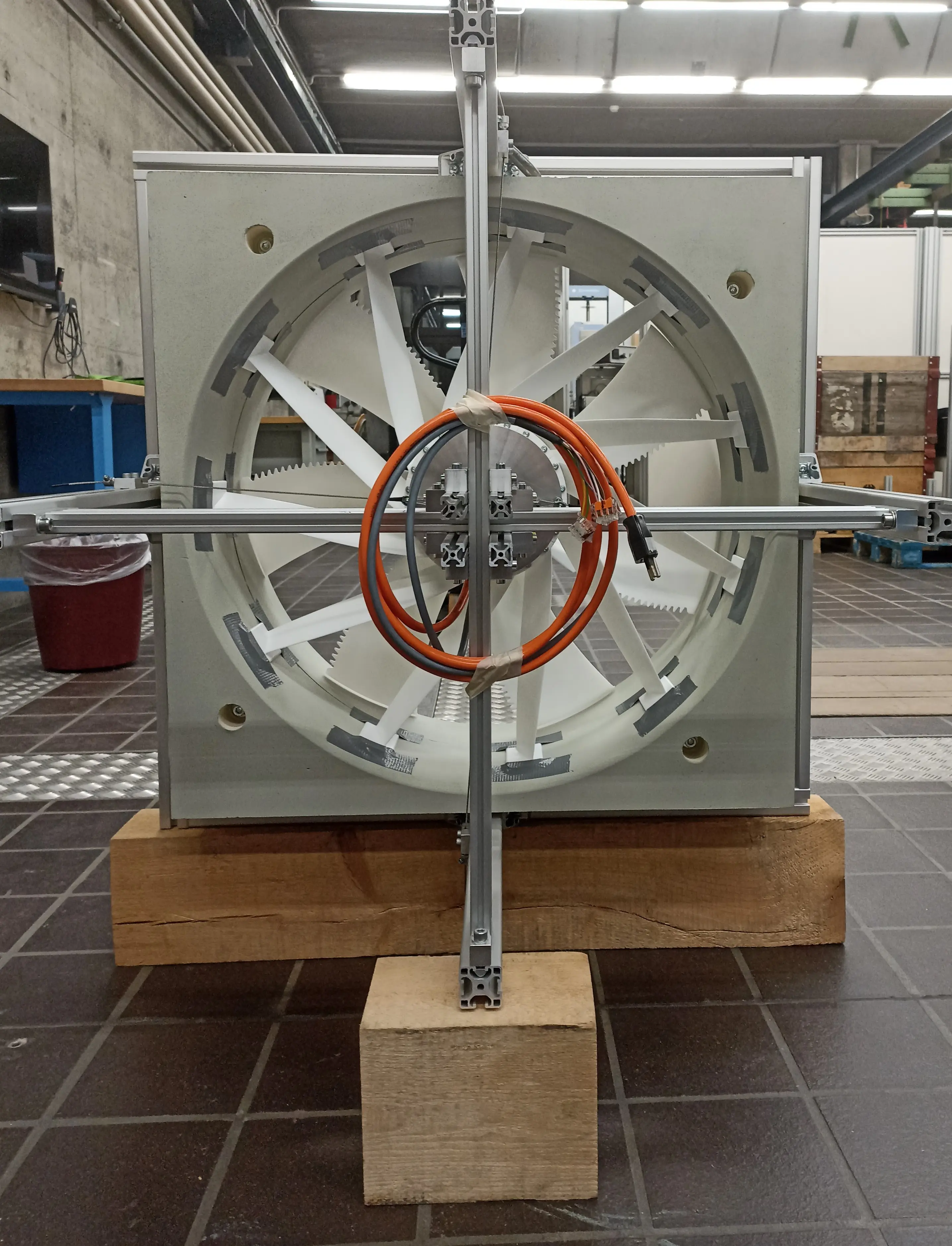

The automatically created designs were imported into a CAD system and geometric details were added with the goal of reducing the noise emissions even further. The final geometries were 3D-printed with selected laser sintering and mounted on a modular test rig developed in the scope of this project (Figure 3).

Our project partners at Empa and OST measured the acoustic and aerodynamic performance of the different designs, respectively. Additionally, similar fans from different manufacturers were measured as a reference. The comparison between our best designs and the reference shows that we could improve the acoustic performance even more while keeping the required volume flow and fan pressure.

At a glance

Project team: Marcello Righi, Christian Hauschel, Sven Düzel

Project volume: CHF 210k

Project status: pending

Third-party funding: yes

Project partners: Kunststoff Schwanden AG, Empa, OST

Contact person : Marcello Righi