Research area: Digitalisation in Machines

Digitalisation in mechanical engineering offers great potential for increasing added value in product development, production and product use. To achieve this, various methods and solutions are being developed in the Digitalisation in Machines research area that enable the entire process, from the idea to the end of the product or the closing of the material cycle, to be mapped in an entirely digital way. These include PLM (product lifecycle management), Industry 4.0, digital twin, 3D master and mixed reality among others. These solutions and systems are adapted to the needs of the industry and are attuned to customer benefits and the business case.

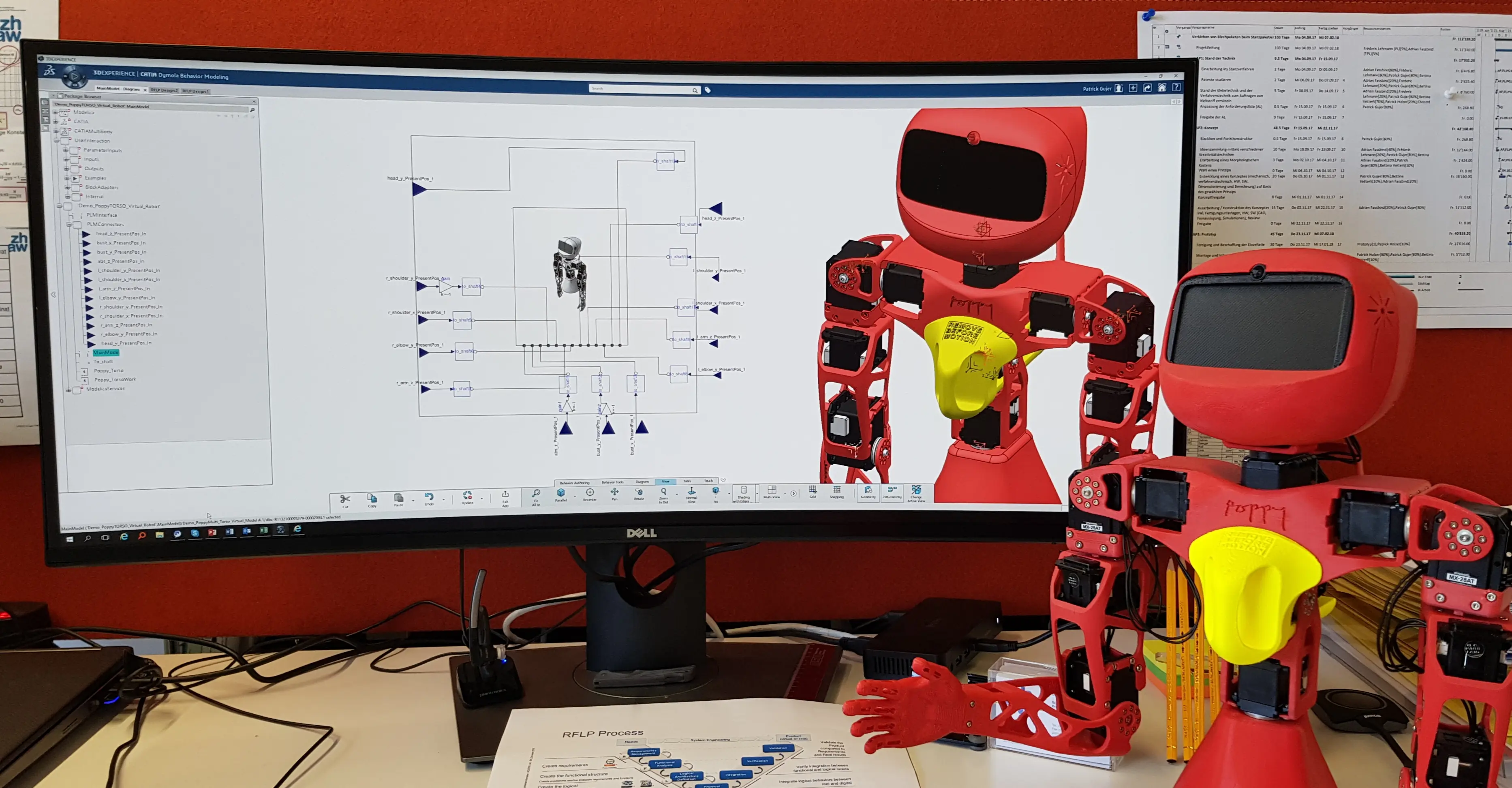

As an award-winning Education Centre of Excellence, we are experts in the use, research and training of Dassault Systems' 3DExperience solution. By using 3D tools and 3DExperience know-how, we can accelerate the creation of innovations and improve the quality of products. The virtual representation of the real world in the form of 3D prototypes also supports the areas of design, marketing and management. We optimise the process flows in CAx applications with customised simulation tools, CAD automation programs and interface solutions.

We offer comprehensive support for the introduction and use of 3DExperience in companies. This includes installation and specific training on 3DExperience to enable companies to benefit faster and more successfully from the advantages of 3DExperience.

Contact

Please get in touch if you would like to discuss your project ideas with us.

Peter Hug, Head of Digitalisation in Machines

Dr. Daniel Schmid, contact person for Digitalisation, Industry 4.0

Platform

Reference projects