Energy Self-Sufficient Monitoring System with Edge Computing for Industrial Pumps

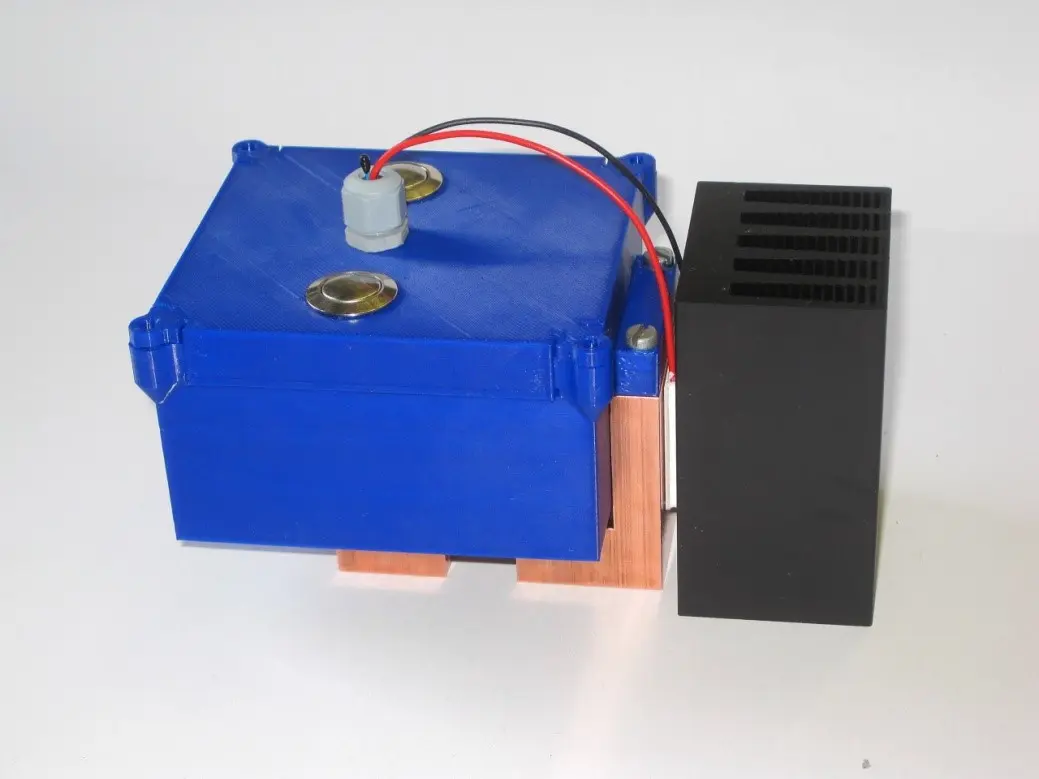

We developed a self-sufficient monitoring system for industrial pumps with the company Sulzer AG, Winterthur. It combines edge computing with energy harvesting and works without a cable or battery. The system obtains its energy entirely from the temperature difference between the pump housing and ambient air using a thermoelectric generator (TEG). Even from a temperature difference of 3 °C, the system collects sufficient energy to conduct regular complex analyses and perform all calculations directly on the device (on the edge). The results are transmitted to a gateway using energy-efficient radio transmission. Even in complex industrial environments, the measured range is about 50 m. The gateway forwards the data to a central server.

The energy self-sufficient device permanently records the most critical data of running pumps in the industrial environment. All necessary calculations are performed directly on the device. It detects increased vibrations and blocked pumps immediately, even when the pump is starting. An extended analysis is also carried out directly on the device at regular intervals. Irregularities (e.g., prospective storage damage) are thus detected early and reliably and reported at the latest within 6 hours. The measured data can be requested from a central location via radio for extended error analyses.

The prototype has a small, industrial-grade housing that is attached to the pump housing with a single screw. A high-resolution accelerometer is attached directly to the structure to guarantee high measurement accuracy.

After successful functional tests in the technical center of Sulzer AG, Winterthur, a field trial was carried out in the Werdhölzli wastewater treatment plant. The system has been shown to work reliably during uninterrupted use under realistic conditions for over 6 weeks. The temperature difference between the bearing housing and the environment was less than 6 °C.

The results can be transferred to condition monitoring applications in other areas. Energy harvesting can provide enough power to operate sensor systems with accurate measurements and complex calculations. The reliability requirements for condition monitoring applications can also be met in harsh industrial environments.