CFD study of a SCR mixing tube with urea injection

Initial Conditions

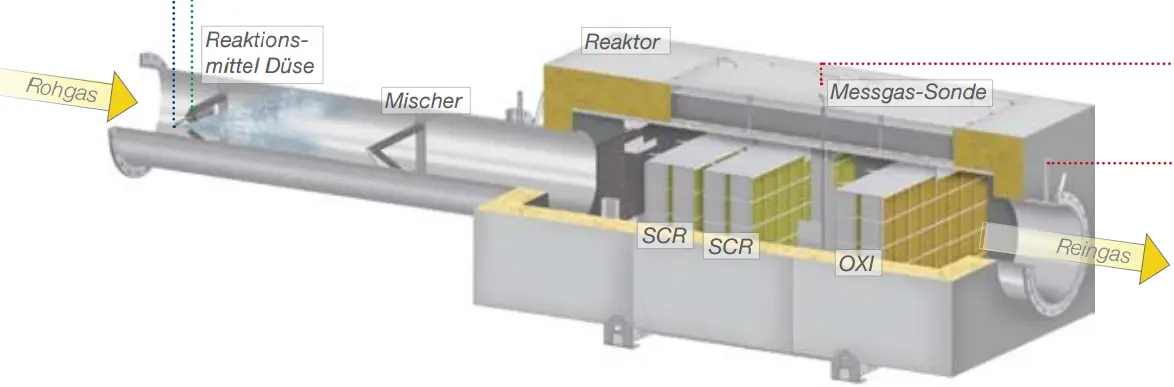

Today, Selective Catalytic Reduction (SCR) is the preferred method to reduce nitrogen oxides (NOx) in the exhaust gas of combustion engines and to meet the applicable exhaust standards, such as the US standard Tier, or the Euro-Norm. Using modern plants, this method can reduce nitrogen oxides by up to 98 %. This requires the reactant ammonia, which reacts with the nitrogen oxides and oxygen to nitrogen and water. The ammonia is produced by feeding a urea-water solution into the injection and mixing tube, where it is reduced through thermal decomposition and hydrolysis. The goal of this project is to record this process in the mixing tube numerically and to obtain insights that aid in the enhancement of plants of this kind.

Results

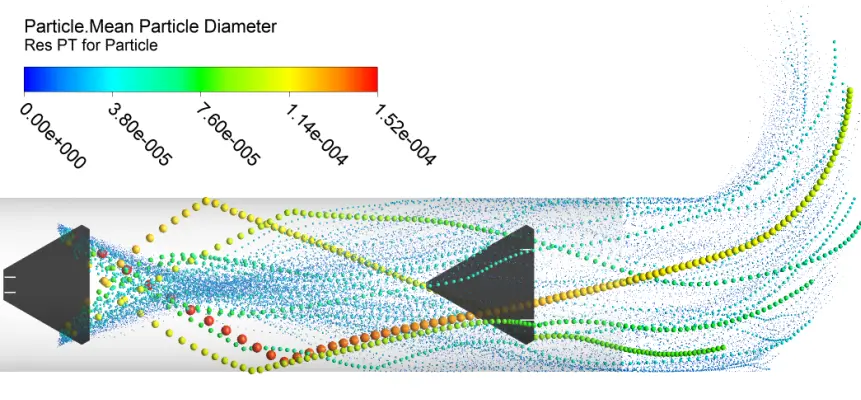

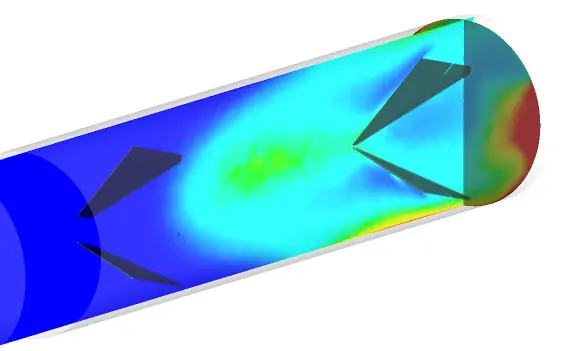

In the context of a Master's thesis, the processes of the mixing tube were simulated with urea injection. The exhaust gas was present in the form of a continuous fluid and the urea drops as discreet particles. Using the Lagrange approach, the trajectory of the urea drops, the water vapour, the decomposition of the urea in ammonia, as well as the quality of the mixture of these components in the exhaust gas could be analysed numerically. The CFD analysis showed that a strong various pipe curvatures create severe torsion, which prevents the typical development of vortexes in the mixed elements, thereby achieving a low mixing quality. An additional simulation showed that this can be counteracted with rectifying elements to improve the mixing quality.

At one glance

Involved Institutes and Centers:

Project Status: completed

Project details

Download Project Flyer: SCR Urea injection(PDF 368,2 KB)