Process Engineering

The laboratory of process engineering develops new and optimizes existing procedures and processes.

The core areas are separation processes, material conversion as well as particle technology and catalytic processes. We focus on the industrialization of new processes and the intensification of existing ones. Modern installations and equipment on a laboratory and a pilot scale as well as state of the art analytical instrumentation support our research and our inspiring and applied teaching.

Process development and optimization

- Thermal, chemical and mechanical separation processes

- Particle production and encapsulation

- Reaction engineering

- Scale-up and process intensification

- Recycling and product work-up

- Catalytic processes and catalyst development

- Materials and processes for energy conversion and environmental technology

- Fuel and gas/flue gas treatment

- Water and waste water treatment

Pilot Plants and Analytics

- Multifunctional ChemReactor (up to 50 litres)

- Rectification and evaporation (up to 250 litres)

- Membrane and mechanical separation plants

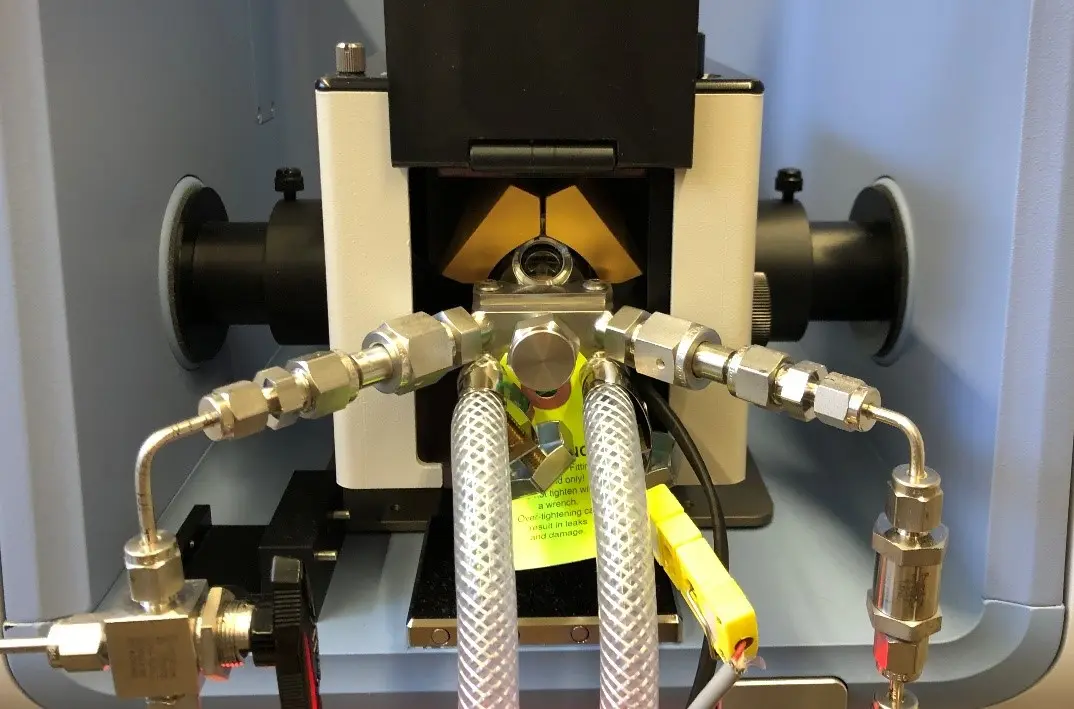

- Pilot plant for supercritical CO2 extraction

- Thermal and Pressure Swing Adsorption

- Ex-protected premises

- Chemi- and physisorption (TPO, TPR, TPD, BET)

- Process analytics: Online, inline (IR, Raman, MS, GC)

Applications

Powder synthesis in the range of 2 μm - 2 mm

Separation of microparticles

Extraction of natural products

Heterogeneous catalysis

Power-to-X and renewable energy sources

Reaction kinetics with FT-IR modulation spectroscopy

Solid Oxide Fuel Cells (SOFC)

Desulfurization of process gas for fuel cells

Optimization of galvanic processes