Inspection robot: measuring oscillations with a microphone

The aim of the inspection robot project was to evaluate an alternative method for wedge tightness measurement, based on a mechano-acoustic approach.

Typically, the response of a wedge to vibration excitation is measured with an accelerometer. In order to obtain optimal measurement results, mounting with a threaded steel stud is the most suitable solution. However, this makes temporary mounting, as it may be needed e.g. for single measurements within a production process, impossible.

The aim of the inspection robot project was to evaluate an alternative measurement method, based on an acoustic sensor (microphone), in order to avoid the abovementioned problem. A piezoelectric actor was developed for the simple excitation of the analysed structure. The measurement principle is based on the analysis of the response spectra of the excited structure. Assessment of attenuation as a measure for input tension can be taken into account as additional factor in the analysis.

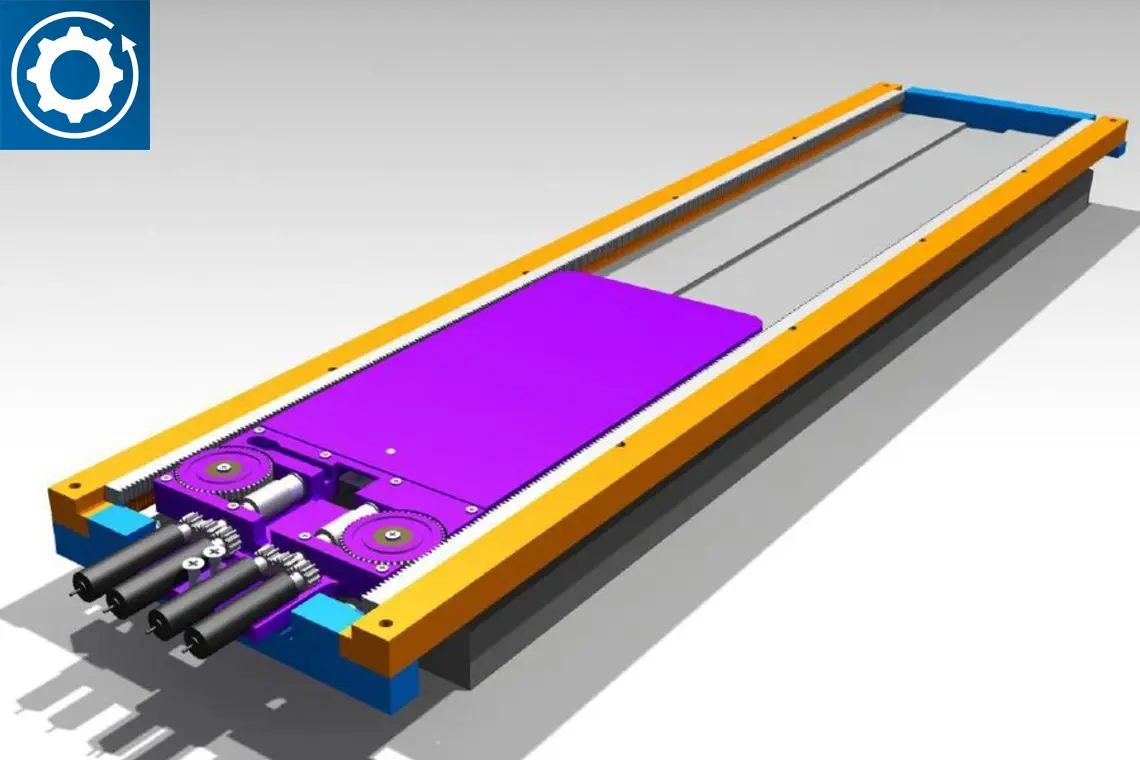

The project also included the development of a ready-for-use hardware component which can be supplemented by a lateral feed unit including controls. This allowed to conduct several tests with different initial tension situations and helped confirming that the newly developed measurement principle is suitable for the desired assessment of a distorted structure.

The project was carried out with RGE and ABB and successfully completed in June 2013.

Project details

Project partners:

Project team: Prof. Dr. Wilfried Elspass, Oliver Tolar, Denis Herrmann