AGILE

Optimising a wind turbine until it is perfect

The AGILE WIND POWER AG company is developing an innovative wind turbine for power generation. It is designed to be compact, noiseless and bird-friendly and offer transportation and installation benefits compared with regular wind turbines. The company is work-ing closely with the ZHAW School of Engineering to maximise the performance of the turbine.

The AGILE turbine represents a technological breakthrough in the world of wind-energy systems. It stands out from the field of customary three-rotor-blade wind turbines both optically and technologically. The AGILE turbine has several horizontally mounted rings that are connected to vertical blades. These can move freely within a specific angle range and adjust themselves according to the wind’s direction. “The turbine rotates like a carousel in the wind, but it is slower than the rotor blades of a regular wind turbine,” comments Patrick Richter, CEO of AGILE WIND POWER AG. “As a result, the material has less stress placed on it and allows turbines to be built in larger dimensions. With this construction design, more energy can be produced in a smaller area, which is a great advantage for suitably exposed locations in the mountains.”

Interdisciplinary collaboration

Discovering which configuration the AGILE turbine should use to achieve the highest possible degree of effectiveness is the research task for the ZHAW School of Engineering. To find out, wind tunnel experiments were prepared, carried out and evaluated over several months under the direction of the Centre of Aviation (ZAV). “The performance potential of the turbine depends among other things on the swivel range and the number of blades,” explains Michael Ammann, who is working on the project on behalf of the ZAV. “The optimum values of these different parameters must be achieved in order to maximise the performance of the turbine.” With the goal of attaining these optimum values, the ZAV as well as the Centre for Product and Process Development (ZPP), the Institute of Materials and Process Engineering (IMPE), the Institute of Embedded Systems (InES) and the Institute of Mechatronic Systems (IMS) all worked together on this interdisciplinary project.

“The performance potential of the turbine depends among other things on the swivel range and the number of blades.”

Michael Ammann, Project Manager Centre for Aviation

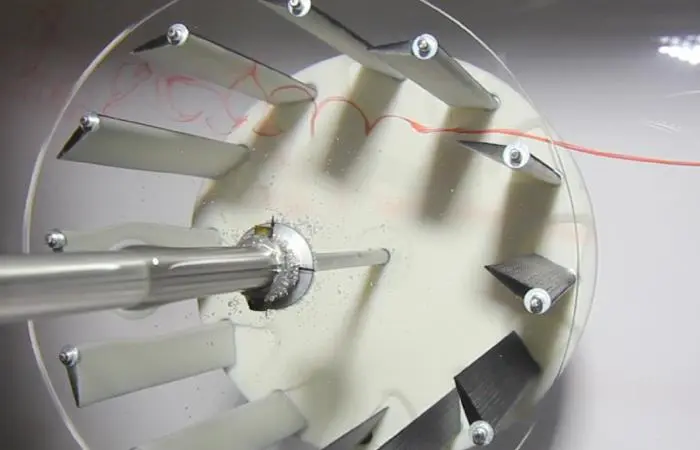

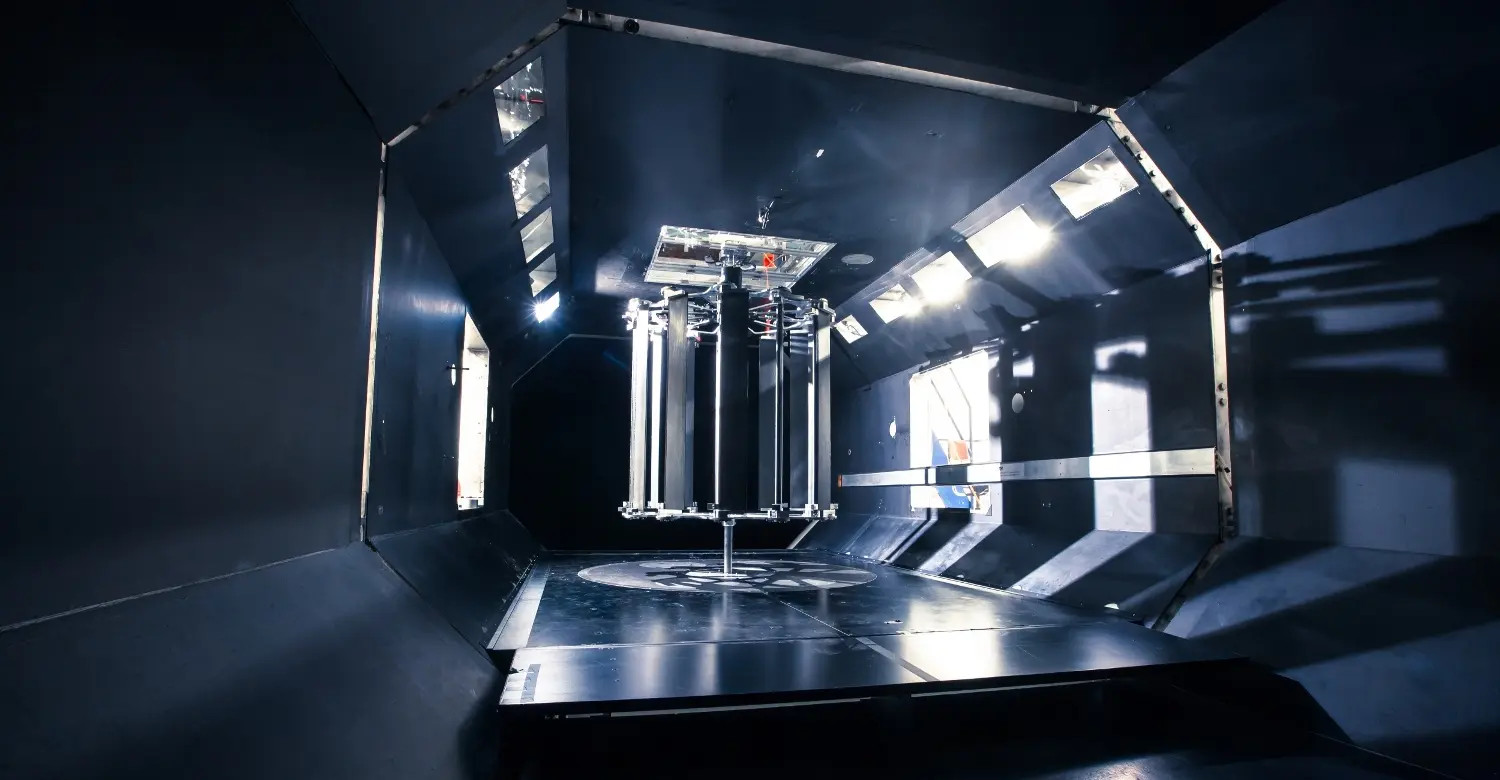

Maximum performance

At the ZPP, a wind tunnel model of the complete AGILE turbine was constructed for the experiment. The special carbon-fibre blades were manufactured in cooperation with the IMPE. The control of the model as well as the data collection system was developed by the IMS and the InES together with Siemens Schweiz AG. The wind tunnel tests themselves were finally carried out in cooperation with the ZAV and industry partner AGILE WIND POWER AG. “We tested various configurations of the turbine and thus quantified the influence of the different parameters on the performance,” Michael Ammann comments. “Our experiments showed that the maximum performance coefficiency can be greatly increased depending on the configuration.” The wind turbine as a unit played a secondary role in this. The focus was on researching individual blade strengths and the swivel angle of the blades. The modular design of the wind tunnel model enabled the individual blades to be installed and removed quickly. This also resulted in valuable insights into the mutual interference of the blades within the AGILE turbine. The air current within the AGILE turbine was also visualised with a second model in a water channel. This smaller model was produced by the ZPP using 3D printers.

“The ZHAW School of Engineering compared the results of calcula-tions of the analytical model with the measurements from the wind tunnel. In this way, the potential of the AGILE technology can be es-timated for the first time.”

Patrick Richter, CEO of AGILE WIND POWER AG

Project with potential

An analytical model of the AGILE turbine was necessary to be able to estimate the performance of larger versions of the AGILE turbine. The basic form for the model was developed at the ZAV and the IMES. This model analytically calculates the force that is applied to the blades of the AGILE turbine. “The ZHAW School of Engineering compared the calculation results from the analytical model with the measurements from the wind tunnel,” is how Patrick Richter describes the process. “In this way, the potential of the AGILE technology can be estimated for the first time.” Now, the further development of this analytical model, with the help of the acquired data from the wind tunnel experiment as well as the field measurements of the prototype, is the next step in this innovative project.

Windturbine AGILE im Windkanal

At a glance

Participating institutes and centres:

- Centre for Aviation (ZAV)

- Centre for Product and Process Development (ZPP)

- Institute of Materials and Process Engineering (IMPE)

- Institute of Embedded Systems (InES)

- Institute of Mechatronic Systems (IMS)

Project partner:

Funding: financial support swisselectric research

Project duration: 2015-2017