Ceramic Materials

In the laboratory of ceramic materials, the complete process chain of synthesis and production of advanced ceramic materials for industrial applications can be reproduced on a prototype scale. A broad range of relevant ceramic materials and production processes is subject of investigations.

The main technical focus of the lab lies on the development of innovative ceramic shaping methods and synthesis of tailored ceramic materials for demanding applications in mechanical, medical and chemical engineering. A comprehensive, universal and modern infrastructure supports the activities.

Synthesis of powders and ceramics

• Powder preparation, e.g. precipitation, colloidal processing

• Powder surface modification, selection and design of process additives

• Polymer derived ceramics

• Shaping, e.g. casting, pressing, new shaping techniques

• Additive manufacturing, 3D printing – stereolithography, powder printing, microextrusion

• Coatings (polymer derived ceramics, sol-gel, enamel, glazes)

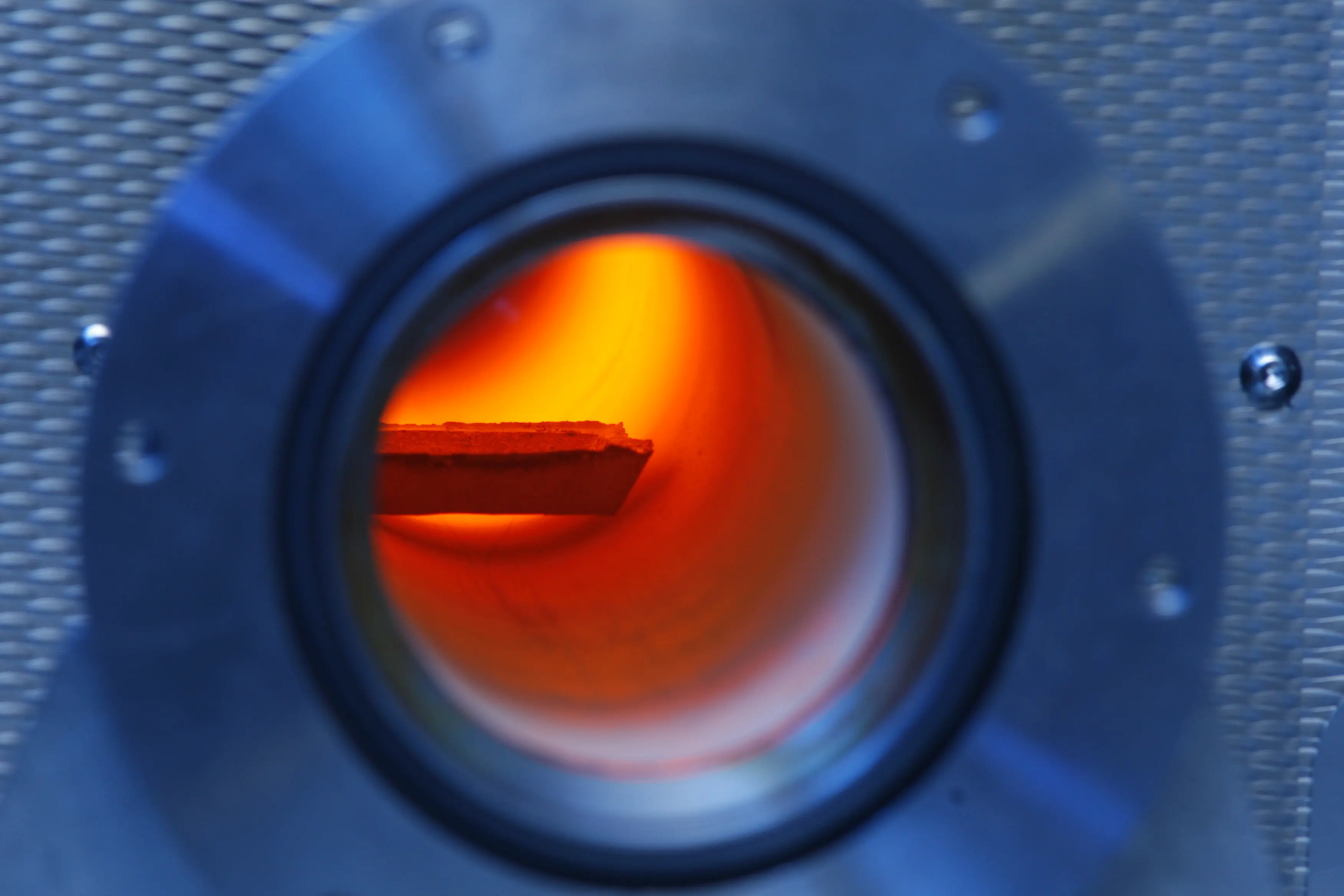

• Sintering, up to 1800 °C under vacuum, reactive or protective gases

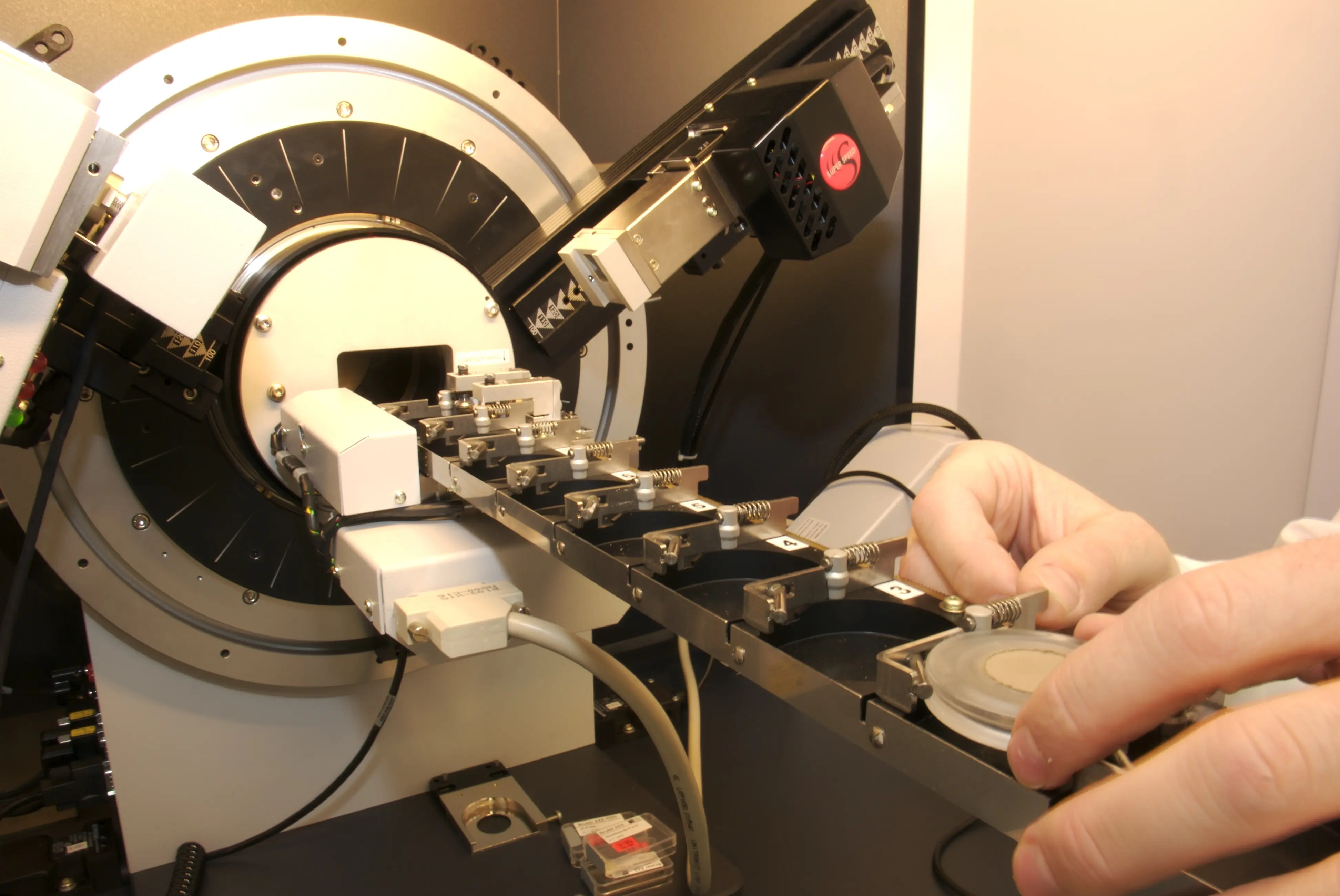

Characterisation

Applications

Advanced ceramic materials are used in a wide range of industrial applications as functional materials e.g.

• Separation (membranes, filters)

• Electronic devices (active and passive elements)

• Energy conversion (SOFC Fuel Cells, batteries)

• Thermal management (insulation, thermal barrier, refractory materials)

• Materials for extraordinary mechanical and chemical property requirements

Flyer Ceramic Materials IMPE

Flyer Ceramic Materials IMPE (PDF 1.92 MB)

Flyer Keramische Materialien IMPE (PDF 1.92 MB)