RAAS: Robot-based assistance system for welding processes

The robot assisted assembly system RAAS was developed to alleviate the assembly of parts that need to be welded together. In this system, the assistant robot grips and positions the parts that need to be connected, afterwards the welds are applied by an experienced welder.

Metal working includes sub-processes like cutting, positioning and welding. During the cutting and welding stages, high efficiency is guaranteed even for small unit numbers thanks to fully automated molding presses, laser cutting equipment, milling machines and welding robots.

However, putting together the welding constructs for small numbers is usually manual labour, since automated solutions are difficult to realise. Thus, Swiss metal working companies lost competitivity compared to companies in countries with lower wages. The aim of the RAAS project (co-financed by KTI), in which the IMS worked with Neuweiler AG, was to partially restore this competitivity by developing a robot based assistance system.

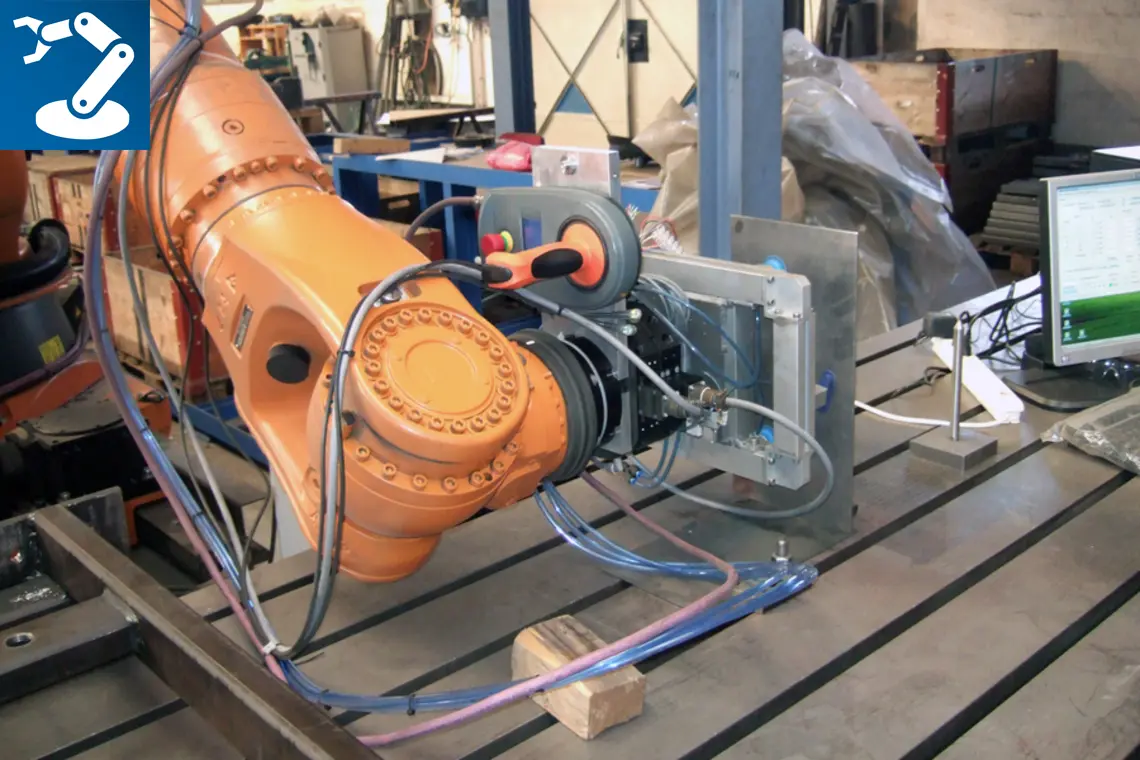

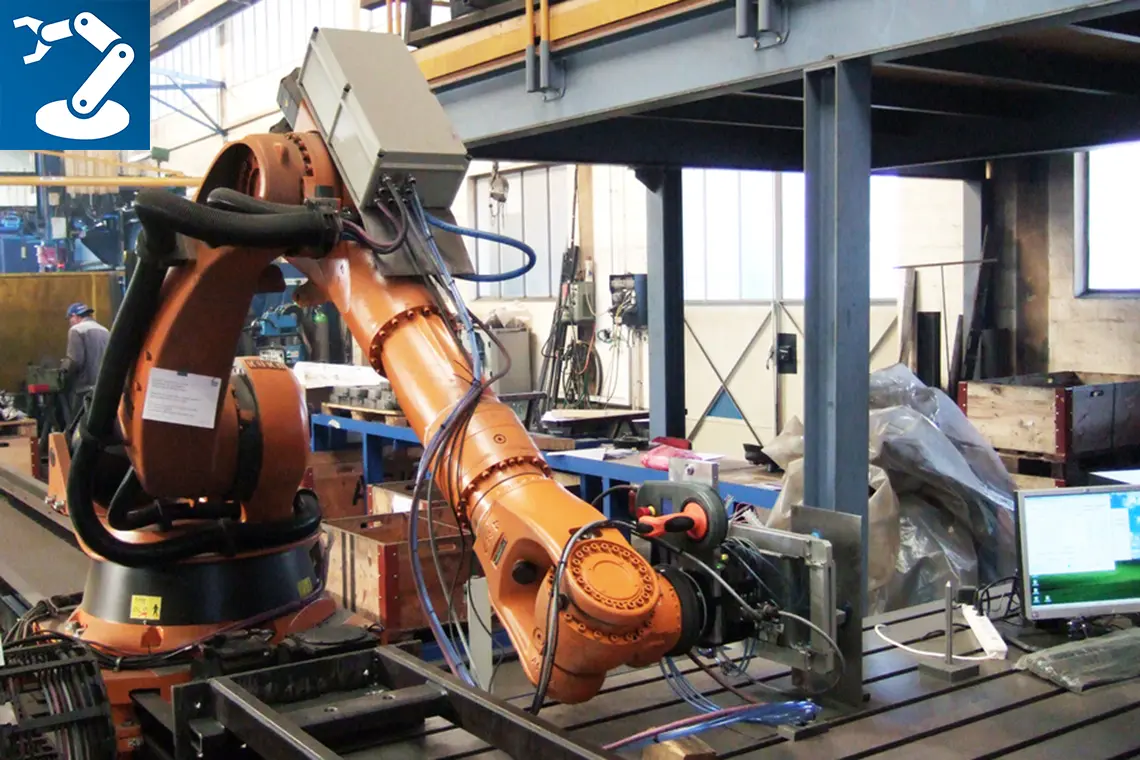

The implemented assistance robot grips the parts and positions them according to the orders given through the user interface and based on a measuring system. The welding specialist can then easily staple the parts together. Thus, the robots capacity for highly precise movements is optimally combined with the flexibility, intelligence and experience of the welding specialist. Since the worker acts within the working area of the robot, safety requirements were high.

The use of such an assistance system was intended to increase the efficiency of the stapling process by a factor of 5 to 10 for very small unit numbers already. Furthermore, the models previously used for the positioning of the parts to be welded could be eliminated.

Link to our project partner:

RAAS in action:

Contact IMS:

-

ZHAW School of Engineering

Institute of Mechatronic Systems

Technikumstrasse 5

8400 Winterthur