Advanced Imaging and Machine Learning for PV Quality Assurance

A multispectral-imaging setup is developed for investigating lab-scale solar cells and for obtaining spatially resolved information about the cell quality. Machine learning is used to esti-mate parameters for a physical FEM model that serves as a digital twin for further optimization.

Contributors: M. Battaglia, E. Comi, C. Kirsch, E. Knapp, B. Ruhstaller

Partner(s): Fluxim AG, Solaronix AG

Funding: Innosuisse

Duration: 2022–2024

Next generation solar cell technologies are researched intensively to further increase efficiency and reduce cost of photovoltaic energy production. The probability of defect occurrence due to inhomogeneity of the deposited layers increases in the production of large-area solar cells. For accelerating the transfer from lab-scale cell research to industry-scale module development and production, reliable characterization methods are crucial.

With their spatially resolved information, imaging methods allow for a more detailed characterization of defects and non-uniformities in novel solar cells. Existing imaging methods are often not carried out simultaneously and correlated to investigate a particular cell, moreover, the processing of the image is rarely done with a physical modelling approach but with traditional feature detection routines.

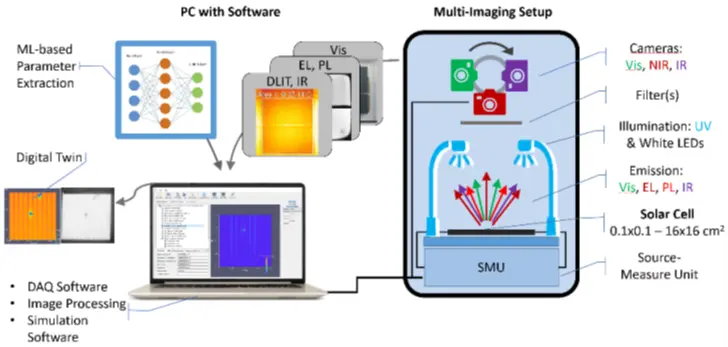

We aim at creating a disruptive measurement setup that combines electroluminescence (EL), dark lock-in infrared thermography (DLIT), photoluminescence (PL) and visual imaging (Vis) in one instrument and connect it to a simulation pipeline that creates a digital twin of the cell. The underlying model parameters are estimated from the images with the aid of machine learning.

Solaronix AG, as a manufacturer of perovskite based solar cells and modules, has a great interest of having a tool available for non-destructive solar cell analysis, being for developments or (in-line) quality control. Solaronix AG will provide solar cells and mini-modules of different types and sizes for measurement setup validation purposes and further analysis of their devices.

A new business opportunity for Fluxim AG is exploited within its range of tools for PV R&D in terms of extensions of existing simulation software and the development of a new measurement setup. Fluxim AG has profound experience in developing all-in-one measurement platforms that are complemented with simulations and with this project wishes to enter the advanced imaging domain.

The project builds upon promising results obtained in a predecessor project where the 2D+1D simulation software Laoss has been extended to the electrical and thermal small-signal domain and machine learning (ML) models of the solar cell were developed with training data obtained with synthetic images computed with the physical model behind Laoss. In this successor project we wish to develop a prototype all-in-one imaging system with incorporated modelling.