Prime: Solutions for flexible assembly systems

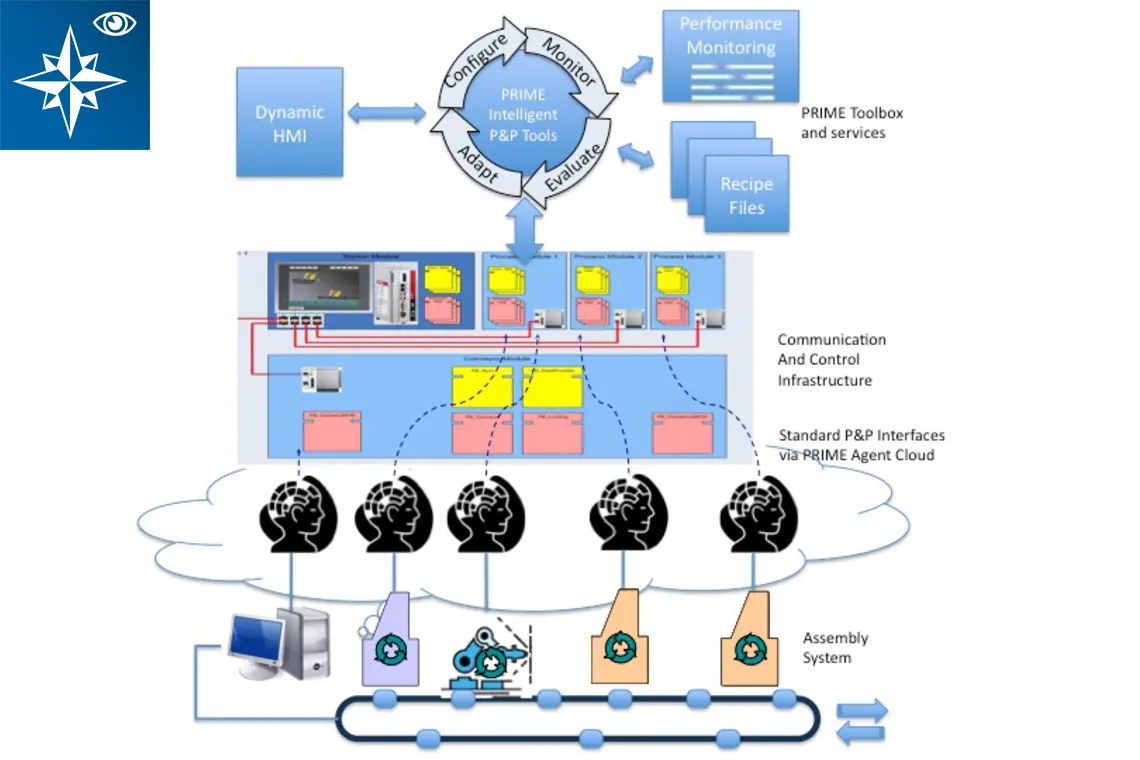

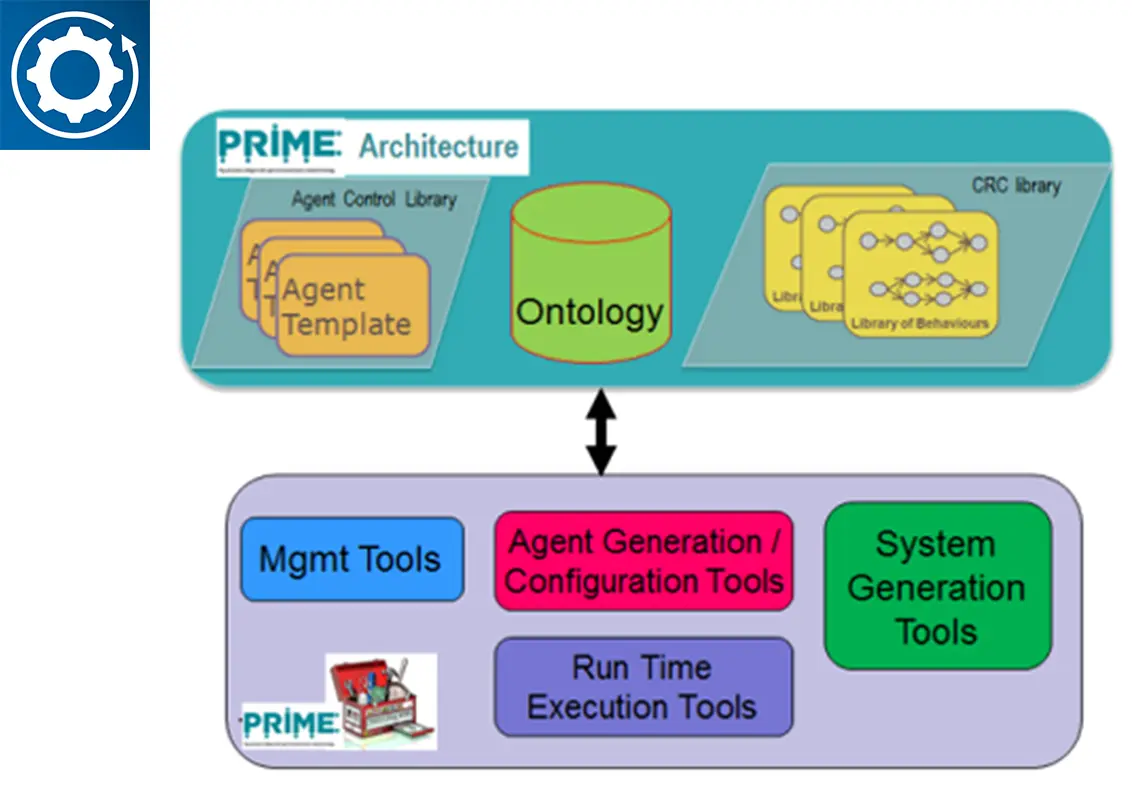

PRIME aims to create new solutions for deployment by small and medium-sized companies of highly adaptive, reconfigurable self-aware plug and produce assembly systems, which will use multi-agent control, dynamic knowledge sharing, integrated monitoring, and innovative human-machine interaction mechanisms.

These next generation assembly systems equipped with PRIME technology will be able to proactively support rapid reconfiguration, adaptation, error-recovery, and operational performance improvement. This will lead to a dramatic cost and time reduction of deploying and maintaining complex assembly systems on demand and improve their effectiveness.

PRIME will deliver a clear progress beyond the state of the art away from current practices segmented into the specification of a new production set-up; ramp-up; production and maintenance and towards the new setting that is characterised by continuous change, where even the boundary between evolution of the current production line and the deployment of a new/different production line is smudged. An important aspect will be that at the same time, the approach and technologies developed can be smoothly introduced in existing operations and with existing hardware.

With the multi-agent paradigm manufacturing systems will become more integrated and more information-rich than before, allowing a new set of manufacturing development tools to be developed that will make the design, control and management of manufacturing systems easier and more robust.

Project details

Project start: 01.11.2012

Project duration: 36 months

Project reference: 314762

- Call (part) identifier: FP7-2012-NMP-ICT-FoF

- Funding scheme: Collaborative project

Project funded by the European Commission

Projektwebseite:

More information is available on the project's website

Links to our project partners:

University of Nottingham, UK (Coordination)