How Industry 4.0 can synchronise output with market demand

The costs of manufacturing in Europe are onerous, particularly for SMEs. Industry 4.0 applications have the potential to enable resources to be used more efficiently. As a member of a European research consortium, the ZHAW School of Engineering contributed to the development of a new intelligent production system.

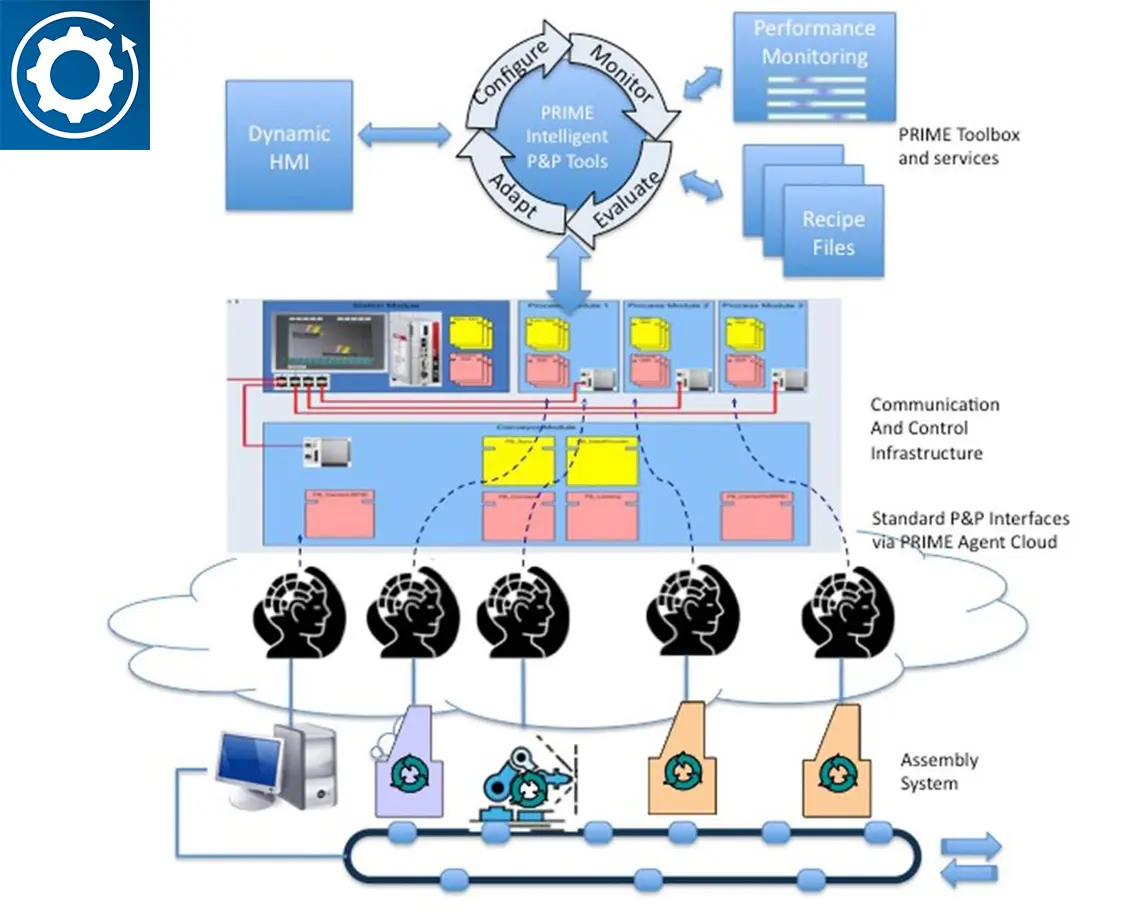

Manufacturing today increasingly involves small production runs, sometimes right down to one single item. Inevitably, the manufacture of individual items means that production installations need to be reconfigured much more frequently, thus making these items more expensive than their mass-produced counterparts. Conversely, when output is switched back to mass-produced items, the quantities produced often exceed actual demand. Whatever their output patterns, manufacturers need to keep their production lines as flexible as possible in order to remain competitive. The research staff engaged in the European PRIME (Plug and Produce Intelligent Multi Agent Environment) project have developed a new way of making manufacturing more efficient in its use of resources.

Production that organises itself is the objective

Under the PRIME methodology, an overarching control system configures the production plant, deploying the individual plant components as and when they become available. “All the components in a modern production line are intelligent mechatronic systems which communicate with each other,” explains Professor Wernher van de Venn, Director of the ZHAW Institute of Mechatronic Systems (IMS). What is more, adds project manager Hans-Rudolf Helfer, the product itself is also intelligent and knows its way around the production process, “In this cyber-physical system, the product negotiates the next production step flexibly with the various plant components.” For manufacturing plants, the principal advantages of using PRIME technology are the speed at which installations can be reconfigured and adjusted, the ability to prevent errors proactively and improved operational efficiency. This should make it possible to achieve substantial reductions in the costs and time required for configuring and maintaining complex manufacturing systems, thus significantly enhancing their efficiency.

«With PRIME we have developed an approach to manufacturing which is fully flexible and can adapt rapidly to fluctuating market conditions.»

Hans-Rudolf Helfer, Project Manager, Institute of Mechatronic Systems (IMS)

Market demand drives output

PRIME is designed to usher in a step change in manufacturing – from the current approach based on clearly delineated process phases towards flexible transitions and continuous evolution. “Hitherto, production plants were simply switched on and produced output at a constant rate until they were switched off again,” says Wernher van de Venn. “Needless to say, that type of production is totally at odds with real market demand, which begins by rising gradually, eventually reaches a peak and then declines again when saturation point has been reached.” As result, there is overproduction at the beginning and end of a product cycle with resources being wasted on output which is never sold. The PRIME system makes it possible to adjust output flexibly, since it is the product itself and market demand which directly control output.

Massive savings in operating and material costs

Specific calculations made by the research team indicate that PRIME enables the components in a manufacturing plant to be used 30 percent more efficiently. This would make it possible to cut production costs and resource use by 25 percent, while at the same time maintaining the same production volumes. “With PRIME we have developed an approach to manufacturing which is fully flexible and can adapt rapidly to fluctuating market conditions,” says Hans-Rudolf Helfer. Having worked as a department head at an automation firm for many years, Helfer is familiar with the needs of industry and can share this knowledge with all those involved in the project. “An important step now will be the seamless integration of the tools and technologies we have developed into existing systems. Communicating with industry – as equal partners as it were – will be particularly useful at that stage."

The project was financed by the European Commission’s 7th Framework Programme. For more information on the project, simply visit www.prime-eu.com.

At a glance

Participating institutes and centres

Project partner:

- University of Nottingham (Koordinator)

- Siemens AG

- SimPlan AG

- TQC

- Asyril SA

- CSEM

- UNINOVA

- TTS - Technology Transfer System S.r.l.

- Introsys

Financing: EU 7th framework programme

Project status: completed