Simulation-Based Calibration of Infusion Systems

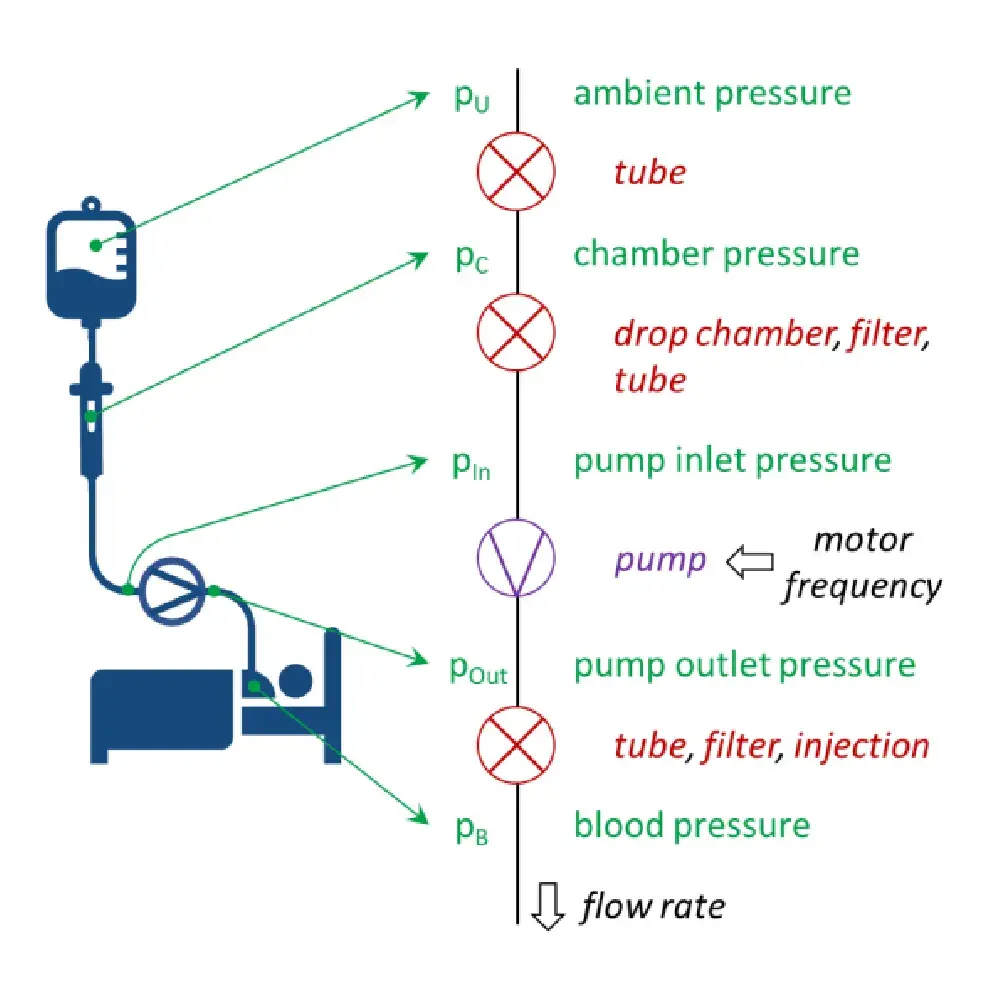

Infusion systems enable the continuous administration of drugs in liquid form. For medical operations, it is necessary to maintain an exact volume flow, which is achieved by using peristaltic pumps. However, the calibration of such pumps requires complex measurements, which impairs the broad application of such systems. By means of a simulation model, the fluid dynamic behavior of the pump and infusion system shall be modeled in order to enable a more efficient calibration and to apply different configurations of the product.

When using medical infusion systems, a high degree of accuracy regarding the amount of injected medication is required. Peristaltic pumps, among others, are used to set the desired volume flow. Since very small volume flows are required, direct volumetric determination of the flow rate is not possible. The flow rate must be determined from the system and pump parameters. For the necessary calibration of the pump, however, individual and extremely extensive measurements are necessary, which considerably limits the efficient use of such devices.

With this model, any configuration of the components installed in the infusion system can be better realized and a broader application of the product is enabled.

Within the scope of the project, comprehensive experimental measurements are used to individually characterize the behavior of all flow-carrying components. Various numerical models (from simple one-dimensional methods to detailed CFD simulations including fluid-structure coupling) are investigated and compared with measurements to characterize the pump and the viscoelastic behavior of the peristaltic tube. Based on the measured data of the individual components and the findings from the characterization of the pump and peristaltic tube, the flow dynamic model of the infusion system is developed, and validated by means of specific experiments.