A Multiple Rotating Reference Frame (MRF) Based Spatial Averaging Methodology for Stirred Reactors

When transporting a vial filled with liquid, the fluid is exposed to external vibrations from the transport vehicle. These vibrations cause motion and therefore shear stresses and pressure forces in the fluid. When it comes to pharmaceutical fluids, it is essential to understand these shear and pressure conditions because they can lead to the degradation of the drug. In certain conditions, droplets can be formed. The presented work investigates the re-impact of such a droplet into the surface of the fluid and the corresponding shear forces using detailed CFD simulations.

The simulation of stirred reactors is challenging as it requires dynamic mesh regions, where the computational cells rotate along with the impeller, with respect to the rest of the stationary domain. OpenFOAM, an open-source computational fluid dynamics (CFD) simulation library, offers several solvers that can handle such dynamic meshes. However, these solvers are inherently transient in nature.

Hence it is computationally very expensive to simulate the whole mixing process since there are stringent conditions on the size of the time steps allowed. Alternatively, an MRF-based method can be used, whereby the body forces due to rotation are introduced for a region surrounding the impeller while keeping the whole mesh stationary. This allows for fast, steady-state simulations to be performed for a fixed configuration of the impeller.

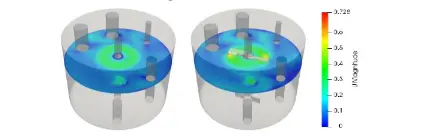

The main idea behind this study is to leverage the computational efficiency of the MRF simulations, by combining a series of them, with the impeller in differing configurations, to derive a spatially averaged flow field. This steady flow field is used subsequently in a transient passive scalar simulation to resolve the concentration of the chemical species in the tank and quantify its residence time.

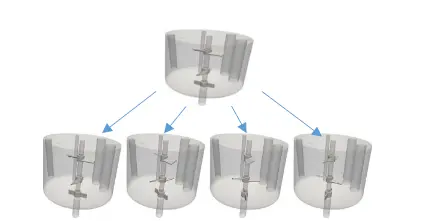

The first step of the methodology requires meshes to be generated at different impeller configurations. To achieve this, a python-based script has been developed, that rotates the input geometry files in STL format by given rotation angles. The generated geometry files are meshed with cfMesh, a highly automatable open-source mesher compatible with OpenFOAM.

On the generated meshes, the steady-state flow field is simulated. These flow fields are subsequently mapped and averaged on a mesh void of the rotating parts. Then the chemical species concentration is simulated on this averaged field for an improved match to experimental data.